Products

Power Battery Emulator

Stropower Battery Emulator System supports battery impedance emulation and charging piler or vehicle loading up to 1200 V 1000 A.

Key words:

Classification:

Power Battery Emulator

Download:

Power Battery Emulator

Power Battery Emulator

Power Battery Emulator has built in battery chemical dominated impedance characteristic which can provide approximated performance compared to real battery PACKs installed in electrical propelled vehicles.

Stropower’s Power Battery Emulator is designed with high power capability and compound battery models in server software ready to use. It is easy-to-use and easy-to-program with adjustment based on user purpose regarding tasks with different batteries in case.

It is also a powerful measurement system for full process-controlled test, providing users with multiple thread for mode shitting, step jumping And fast data acquisition.

Features of Stropower Power Battery Emulator

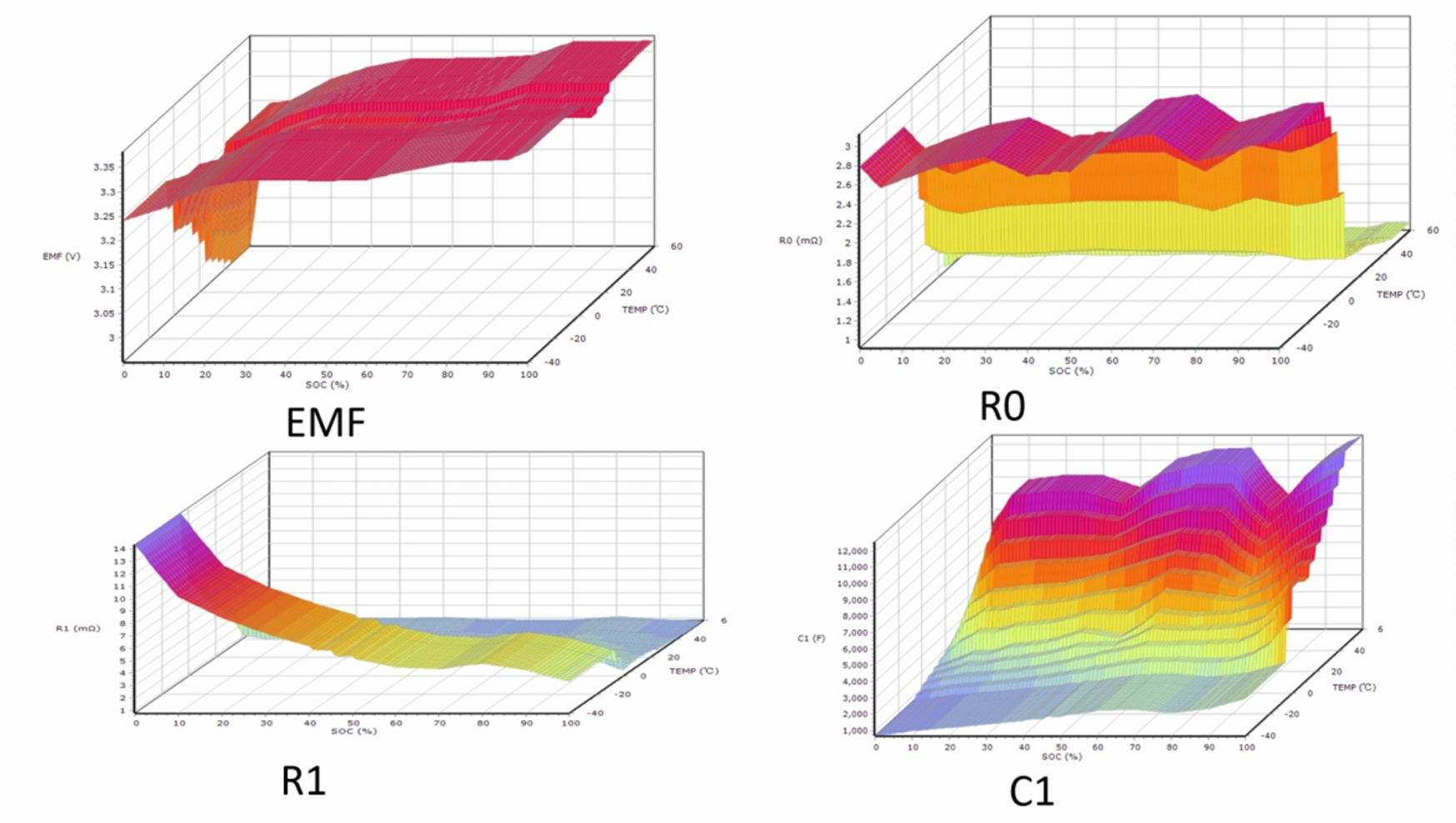

∗ Based on 3 order battery model for Li-ion batteries, providing high accuracy emulation with matrix defined EMF, R0,R1,C1 (*[SoC% Temp.]matrix)

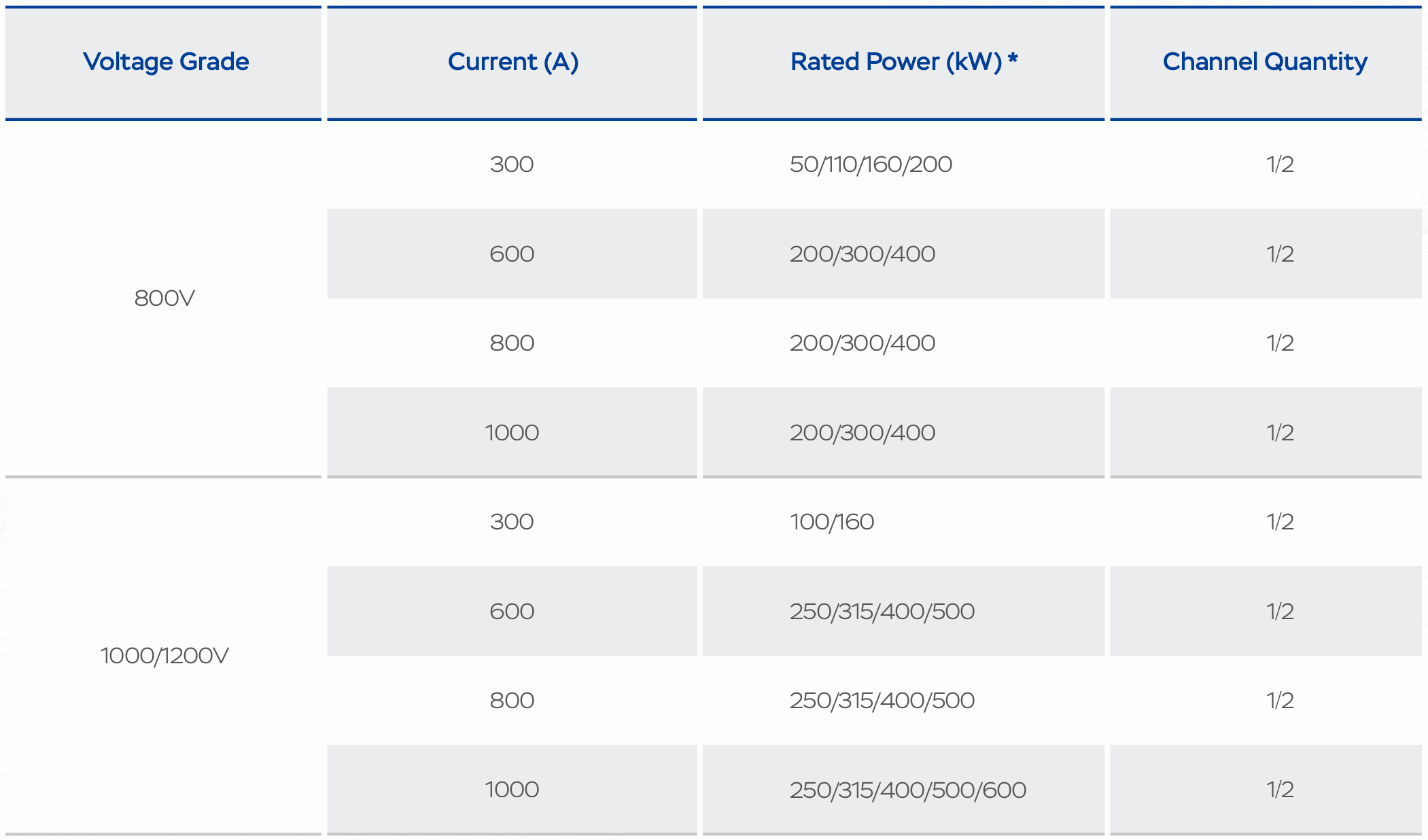

∗ Wider operation range for emulating battery PACKs: 800 V | 1000 V | 1200 V , up to 1000 A

∗ With full functionalities of battery PACK cylers

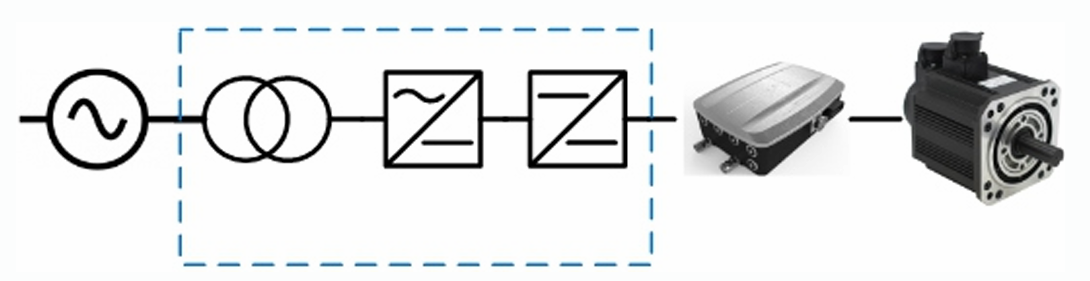

∗ Easy to be deployed in linkage test such as powertrain or other HVEE bench tests

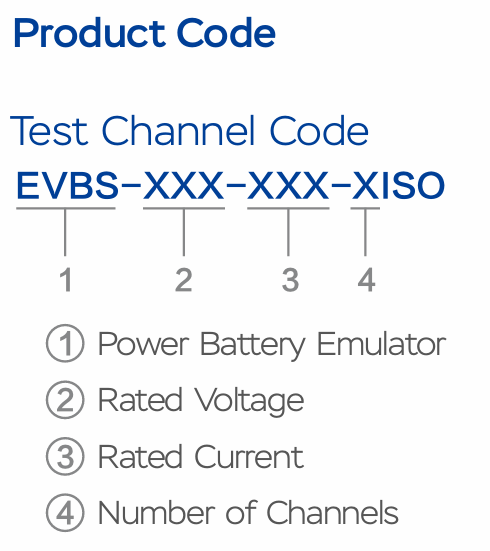

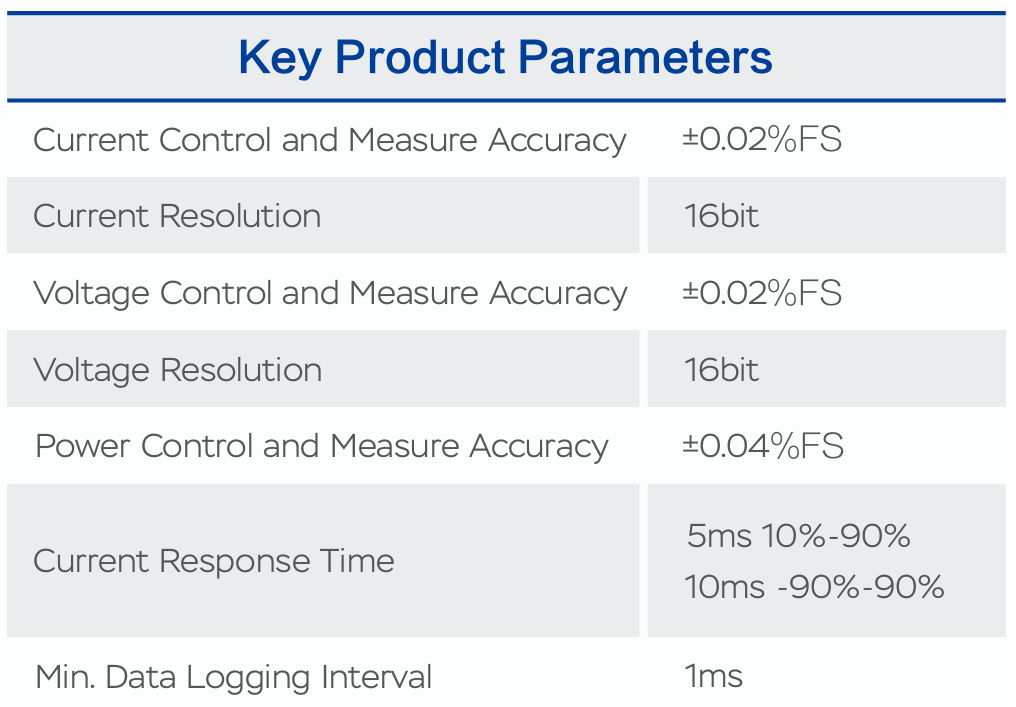

Parameters and Product Code

Operation Specifications and Performance

Characteristics of Stropower Battery Emulator System

∗ Accurate Battery Characteristic Simulation

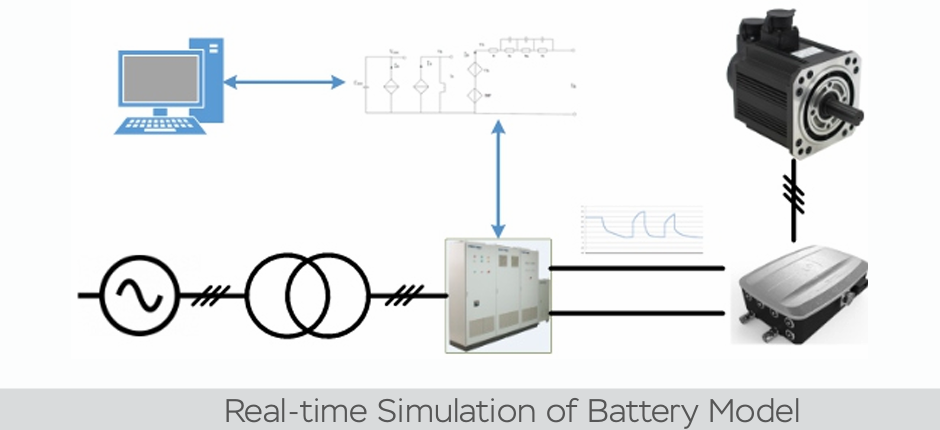

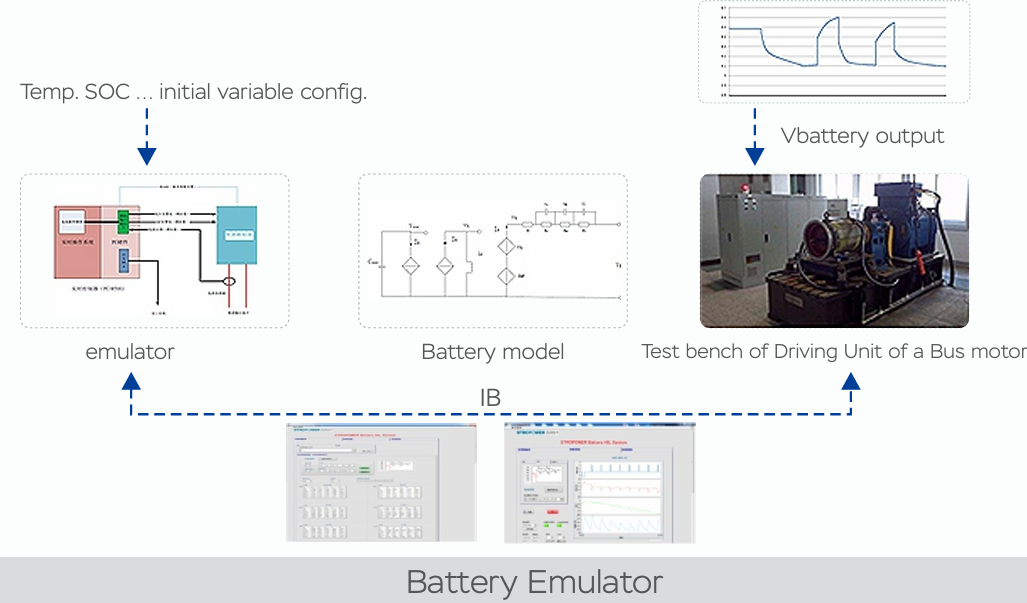

a. An important function of the power battery simulation system is to simulate the battery model in real time during the test. Exhibit external characteristics consistent with real batteries. The following is a real-time simulation of the Stropower battery emulator.

b. Battery type selection is mainly provided to users to choose different types of batteries, battery types include lead acid,Nickel-metal hydride, lithium iron phosphate, lithium cobalt, lithium manganate, lithium nickel-cobalt manganate, etc. The battery model is configured after this, and the system can simulate the battery model, through which the accurate and customized model can be easily realized.

∗ Modular Design with Energy Regenerative

a. Braking energy is fed back to the grid during the test braking conditions

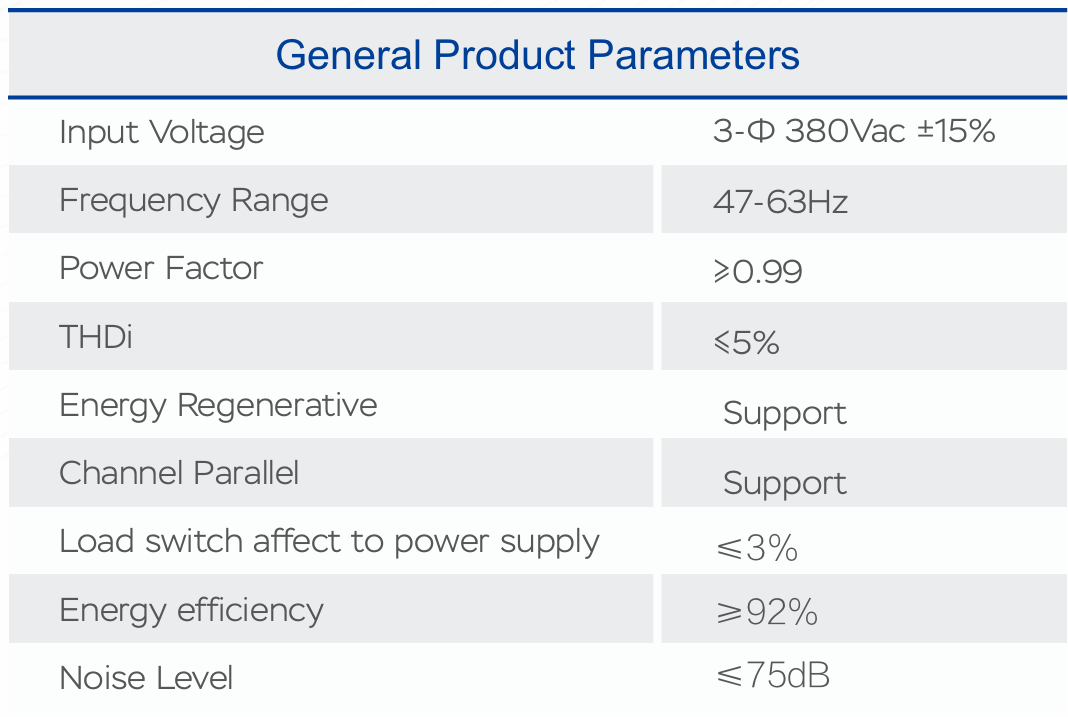

b. The efficiency of the whole machine is high, above 92% under the rated load

c. No need to use power resistors to consume discharge energy

d. Equipment heat dissipation is small, does not increase the air conditioning load

e. Does not pollute the power grid, does not affect other electrical equipment, power factor greater than 0.99, voltage harmonics less than 5%

∗ High Control Performance

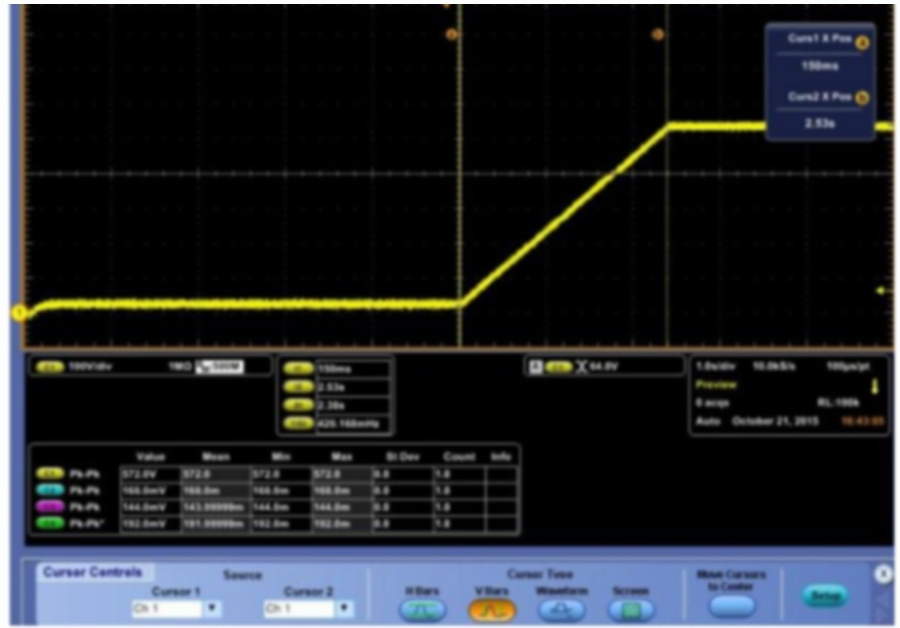

a. < 5ms voltage stabilize time during load transients

b. Voltage accuracy ± 0.02% F.S.

c. Current accuracy ± 0.02% F.S.

∗ Charging Pile Emulator

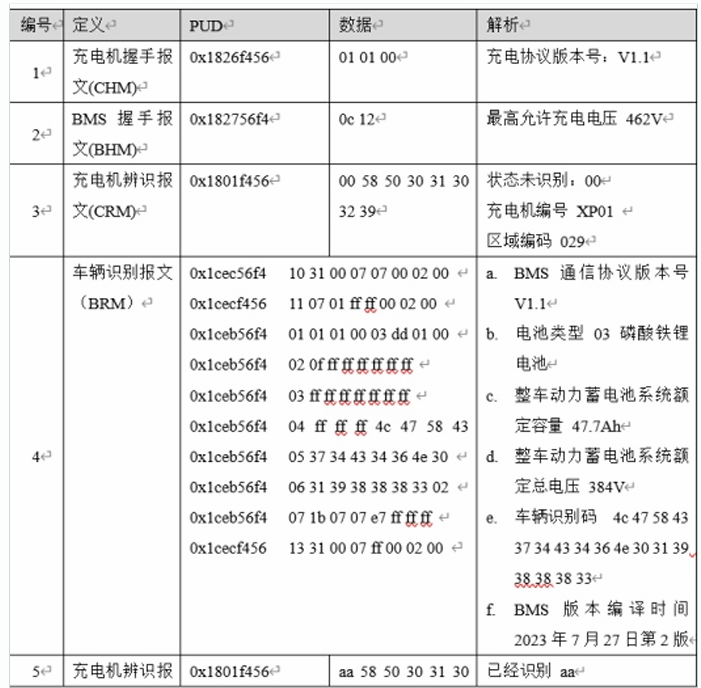

a. The equipment has the function of BMS simulation test;

b. Battery pack simulation: voltage simulation range 100V ~ 1000V;

c. Insulation simulation module: can simulate DC+ to PE, DC-to PE insulation alarm and insulation failure;

d. Integrated GB/T 27930-2015 test function;

e. BHM, BRM, BCP, BCL, BCS and other parameters are adjustable;

f. Can simulate vehicle BMS fault situation;

g. The charger parameters can be read;

h. The timed sending time and timeout judgment time can be adjusted, which is convenient to simulate some electric vehicles whose details are not carried out according to national standards.

∗ Function for Vehicle Simulation Test

a. International Interface Test

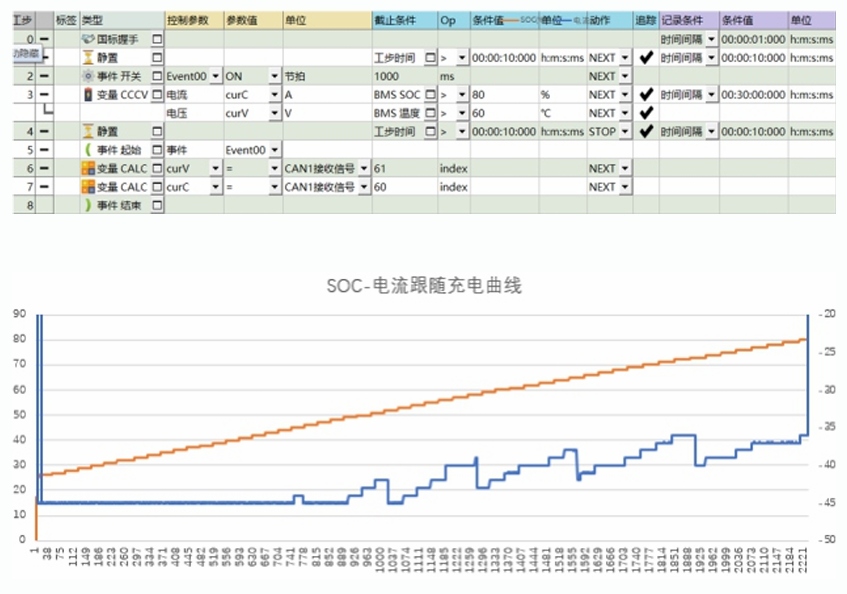

b. Current Following Test

c. DCIR Test

Application User Case

undefined

Online message

* Note: Please be sure to fill in the information accurately and keep the communication open. We will get in touch with you as soon as possible