Products

Battery Cell Cycler

Exceptional control and measure Accuracy and Ultra-fast current Response for cell charging and discharging test.

Key words:

Battery Cell Cycler

Cell Cycler

Charging and Discharging

High Accuracy Battery Tester

Distributed Cell Test

Lithium-ion Battery Tester

Classification:

Battery Cell Cycler

Download:

Battery Cell Cycler

Battery Cell Cycler

Designed with high customization options for users' and customers' deployment for different purpose and requirement to cell level testing on Lithium-ion battery or else chemical based batteries.

Professional Line - CTP series

With mainstream control and measure accuracy and robust system design on hardware and software, offering users high performance and reliable testing platform with relative cost-effective solutions.

Voltage Accuracy on control and measurement: ± 0.05 % F.S. (resolution: 16 bit)

Current Accuracy on control and measurement: ± 0.05 % F.S. (resolution: 16 bit)

Power Accuracy on control and measurement: ± 0.1 % F.S.

Current Response time: response time of 5 ms (10% to 90%) switching time of 10 ms (-90% to 90%)

Data Acquisition time: 10 ms (minimum interval)

AC Measurement function: no ripple test function

Superior Line - CTS Series

With enhanced testing and measurement accuracy and advancing hardware architecture for power stages, offering users higher accuracy per testing requirement, and/or providing an ultra-fast control ability to fulfill complex fast load profile demand. Additionally, AC measurement function is optional for ripple test scenarios.

Voltage Accuracy on control and measurement (up to request): ± 0.02 ~ 0.05 % F.S. (resolution: 16 bit)

Current Accuracy on control and measurement (up to request): ± 0.02 ~ 0.05 % F.S. (resolution: 16 bit)

Power Accuracy on control and measurement (up to request): ± 0.04 ~ 0.07 % F.S.

Current Response time: response time of 3 ms (10% to 90%) switching time of 5 ms (-90% to 90%)

Data Acquisition time: 3 ms (minimum interval) *support 1 ms for 60s maximum

AC Measurement function: ripple test - 100 Hz 120 App (with 5 meter cable) with 50 Adc superimposed

CE Certification Models (due to Aug. 2024)

∗ EMC - EN IEC 61326-1: 2021

∗ Safety - Test Standard: EN 61010-1:2010 + A1:2019

Feature of Stropower Battery Cell Cyclers

Functions of Stropower Battery Cell Cyclers

∗ Negative Voltage Test for forced-discharging is possible with CTS series

∗ Temperature Sampling channels built-in

∗ Multiple Current Range are supported from ENOVA software and hardware supported (*request to technical support for detail)

∗ DCIR Measurement is all model possible for x ms response speed

∗ MES test is possible for additional CAN or LAN linkage

∗ Configurable Variables are free for allocation by ENOVA software

∗ Current Level Gearing is due to multiple sensors built-in

∗ Overall Protection is powered by ENOVA software for step-program-global layers

∗ Pulse Test is fully supported (*request to technical support for detail)

∗ Ripple Injection Test is due to hardware (*request to technical support for detail)

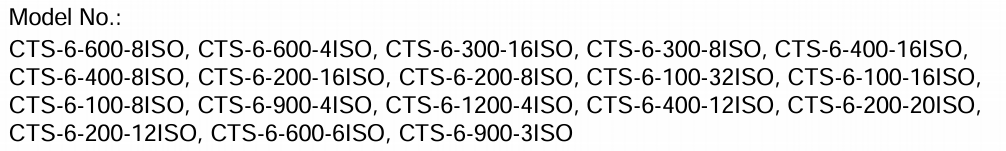

Parameters and Product Code

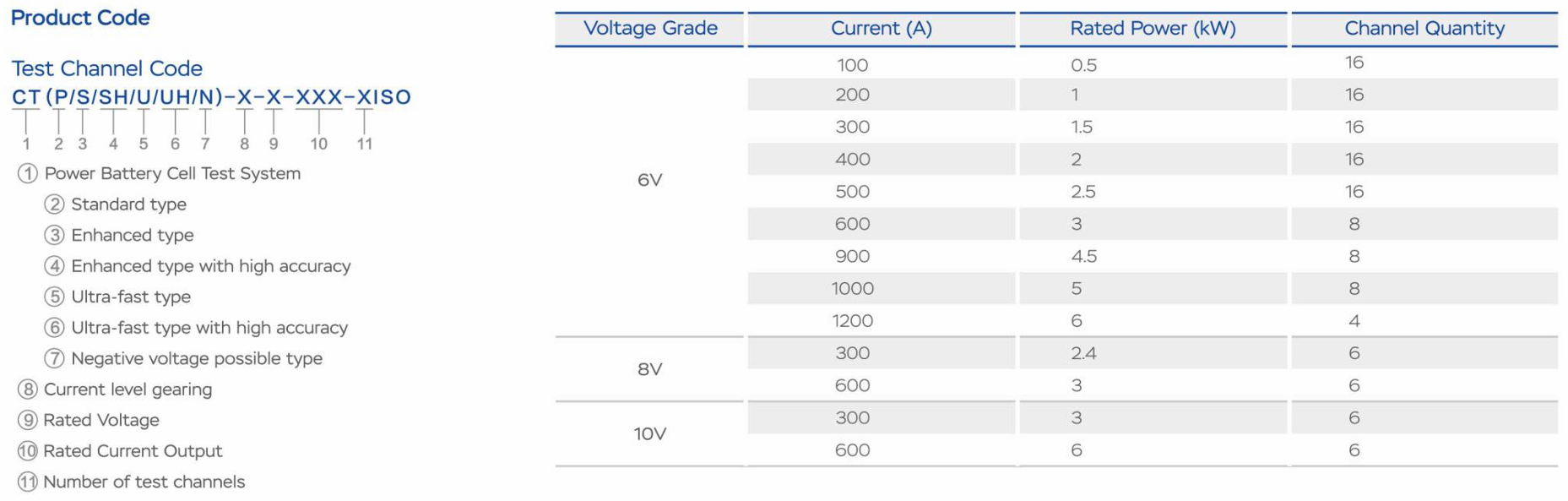

Performance and Configurations

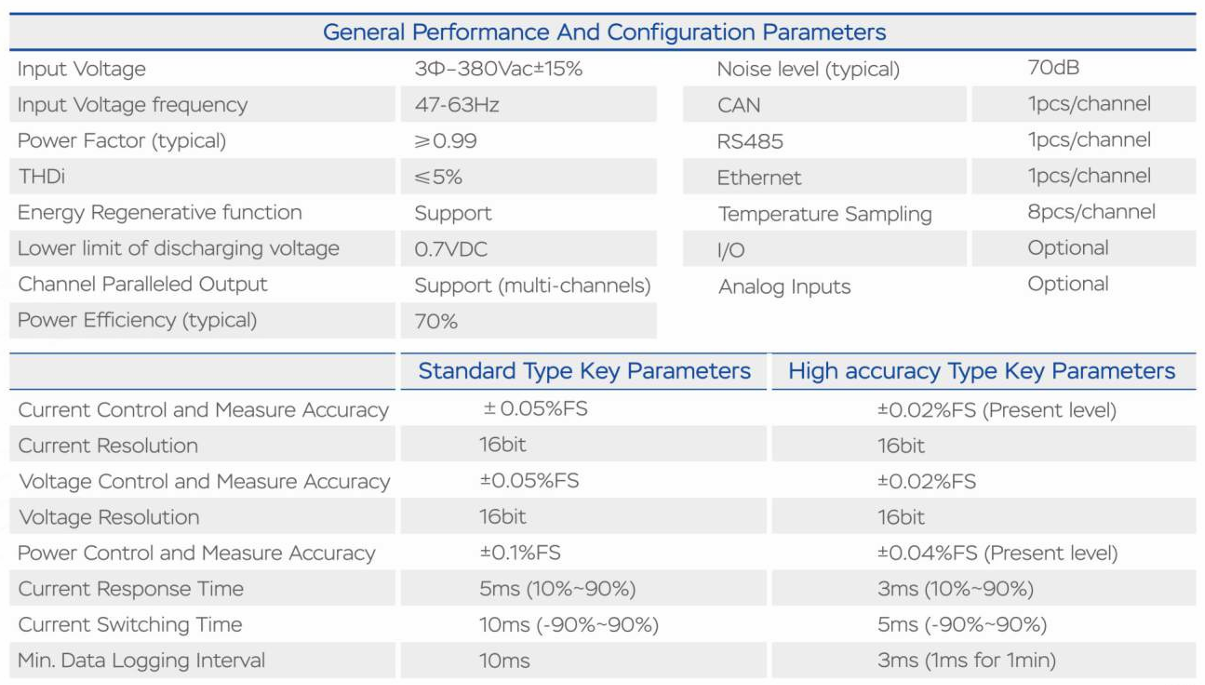

Distributed Test Solution for battery cells

In the case of a large number of cell test channels, because the battery test itself has a difference in charge and discharge time, and it is rarely full at the same time. Therefore, in order to reduce the investment of equipment and rationalize the distribution, the scheme of single-channel single AC distribution of the battery cell is upgraded to multiple - the cell channels share an AC module and power distribution.

It can realize the power feedback in the DC network, and the feedback efficiency is as high as 85% to reduce the input power demand, which can save the total power value of AFE. Reduce procurement costs from each channel operates independently, easy to maintenance and replace.

Benefits of Distribute Test Solution for Battery Cells:

∗ Reduced investment for high quantity test channels

∗ Energy saving based on local energy cycling

Integrated Battery Cell Test Solution

Climate chamber (temperature thermostatic chamber) integrated, saves time for customer users to configure the linkage between cycler and chambers. Overall appearance, more compact, small overall footprint, high space utilization; Power cable and the sampling cables are routed inside the temperature tank, and the cables can be shorter and neat in appearance. Electrical performance characteristics: short power line, less material, low line loss and low operating cost; Integrated control system, convenient for monitoring, good user experience. Integrated input to reduce regional input power distribution design and cable laying costs.

Benefits of Integrated Battery Cell Test Solution:

∗ Overall Appearance for easy lab cleaning and placement

∗ Good user experience cause of the ease to linkage operating

∗ Low wiring cost cause of the shortest cable length for power stage to battery cells

∗ Low power loss thus higher energy saving for testing tasks

Application User Case

undefined

Online message

* Note: Please be sure to fill in the information accurately and keep the communication open. We will get in touch with you as soon as possible