Products

Battery Module Cycler

U Type: Low-to-mid voltage modules (8 ~ 60V) MT Type: High voltage modules (100~500V) Current Capability: 300~1000A

Key words:

Battery Module Cycler

Module Cycler

Charging and Discharging

Module Tester

Battery Module Tester

Lithium ion battery module

Classification:

Battery Module Cycler

Download:

Battery Module Cycler

Battery Module Cycler

Designed with high customization options for users' and customers' deployment for different purpose and requirement to module level testing on Lithium-ion battery modules.

Stropower Battery Module Cyclers have two types specially to meet with low-to-mid voltage modules (8 ~ 60V) and high voltage modules (100~500V) for meeting with different test requirement. Additionally the ASU (Auxiliary Sampling Unit) is usually a sampling attachment to module cyclers for multiple voltage and temperature sampling need.

U Type - High Performance Series

With advanced power stage which enables the module cycler to be used for a wide range of voltages with high performance of control and measurement.

The applicable voltage range are with 8V | 10V | 20V | 60V for U type module cyclers of Stropower.

It is also an option for negative output testing request on to battery cells and modules, which is possible to apply 0V or negative voltage when discharging for some safety tests concerning forced discharging or over discharging.

Voltage Accuracy on control and measurement: ± 0.02 ~ 0.05 % F.S. (resolution: 16 bit)

Current Accuracy on control and measurement: ± 0.02 ~ 0.05 % F.S. (resolution: 16 bit)

Power Accuracy on control and measurement: ± 0.04 ~ 0.1 % F.S.

Current Response time:

a) U Series: response time of 1 ms (10% to 90%) switching time of 2 ms (-90% to 90%)

b) N Series: response time of 5 ms (10% to 90%) switching time of 10 ms (-90% to 90%)

Data Acquisition time: 1 ~ 10 ms (minimum interval) *support 1ms data recording rate for maximum 60s

AC Measurement function: 0.01Hz ~ 1kHz | 1000 App (at 1kHz) | DC current superimposed

MT Type - Module Testing Series

Designed with module level testing voltage levels specially meeting with module level test demand, multiple channel setup making it ideal for power allocation between different channels while keep the power capacity for high power test when time dues.

The module test normally need additional sampling channels for single cell voltages and temperature at different places of DUT, which is optional for Stropower module cyclers to add Stropower ASU (Auxiliary Sampling Unit), please further review the product page for more details.

The applicable voltage range are with 100V | 150V | 250V | 300V | 500V for MT type module cyclers of Stropower.

It is also an option for negative output testing request on to battery cells and modules, which is possible to apply 0V or negative voltage when discharging for some safety tests concerning forced discharging or over discharging.

Voltage Accuracy on control and measurement: ± 0.02 ~ 0.05 % F.S. (resolution: 16 bit)

Current Accuracy on control and measurement: ± 0.02 ~ 0.05 % F.S. (resolution: 16 bit)

Power Accuracy on control and measurement: ± 0.04 ~ 0.1 % F.S.

Current Response time:

a) MTH Series: response time of 3 ms (10% to 90%) switching time of 5 ms (-90% to 90%)

b) MT MTN Series: response time of 5 ms (10% to 90%) switching time of 10 ms (-90% to 90%)

Data Acquisition time: 3~10 ms (minimum interval) *support 1ms data recording rate for maximum 60s

AC Measurement function:on request

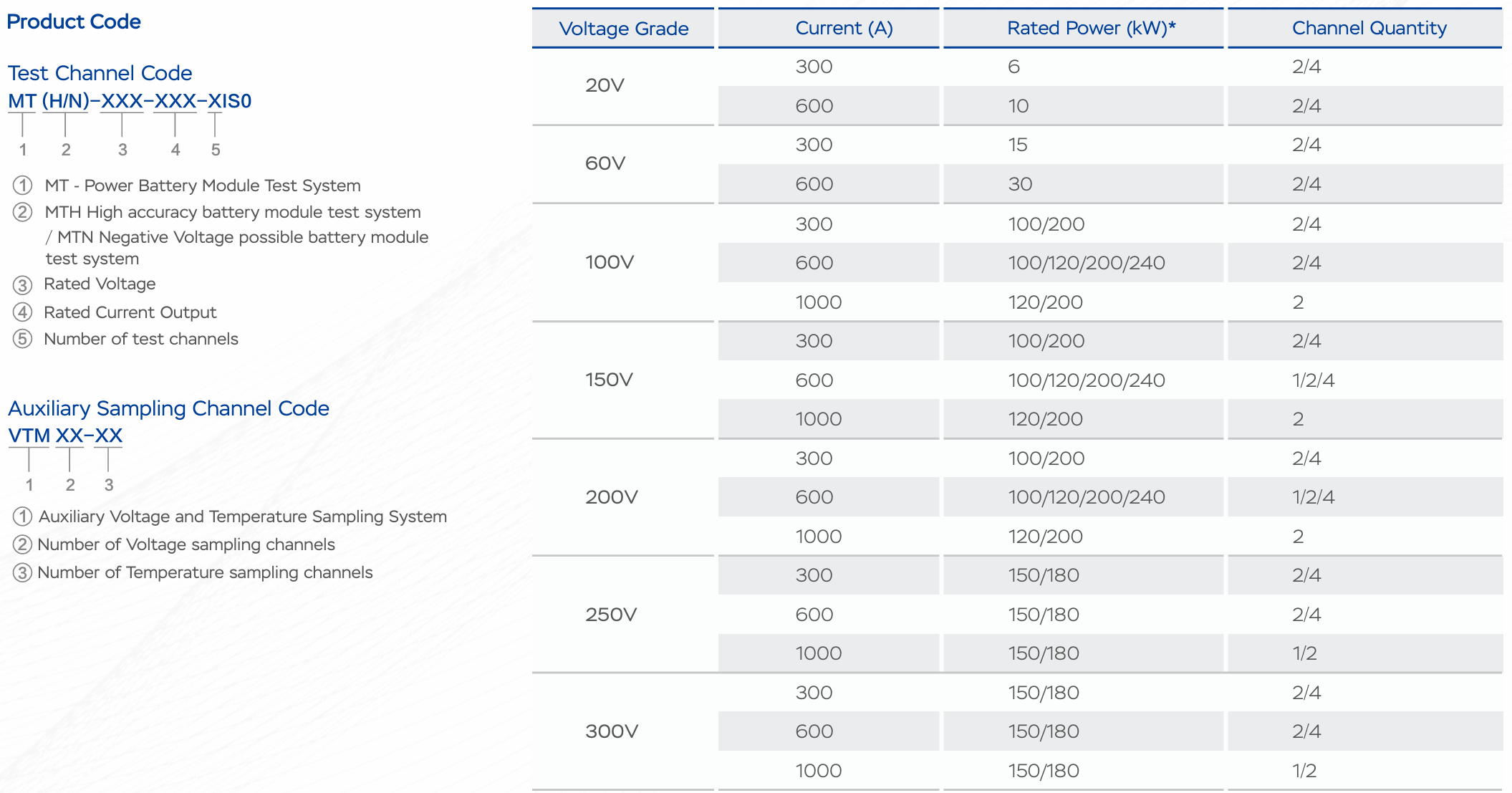

Parameters and Product Code

∗ Customized options are up to request if there is deviations to existing model

∗ Negative Voltage Possible models are built-with H bridge that reverse voltage is ready to be programmed

∗ Over-discharging or forced-discharging is possible with Negative Voltage Possible models

Remark:

20V | 60V are named with single channel power, 100V and above are named with cabinet power (free allocation in one cabinet)

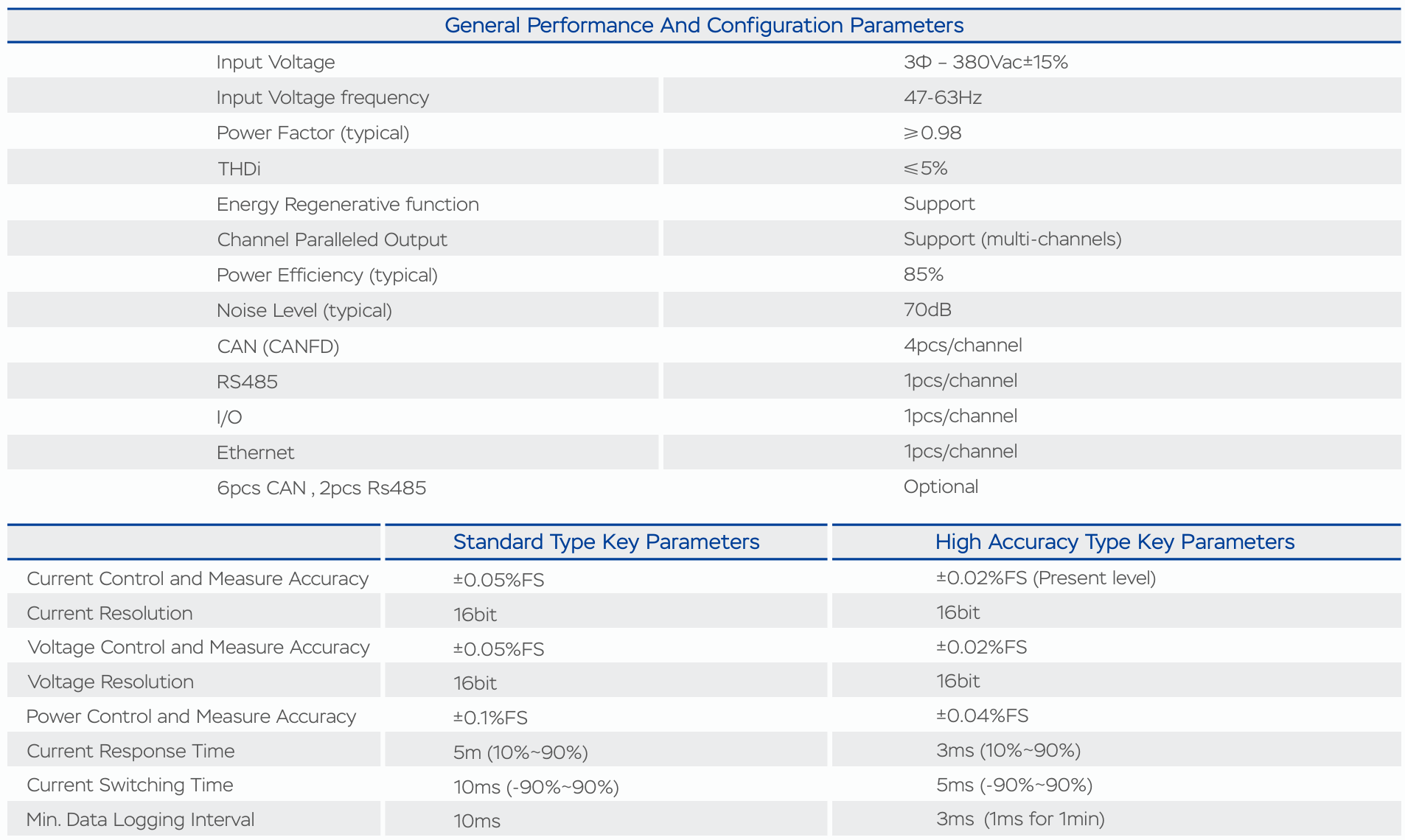

Performance and Configurations

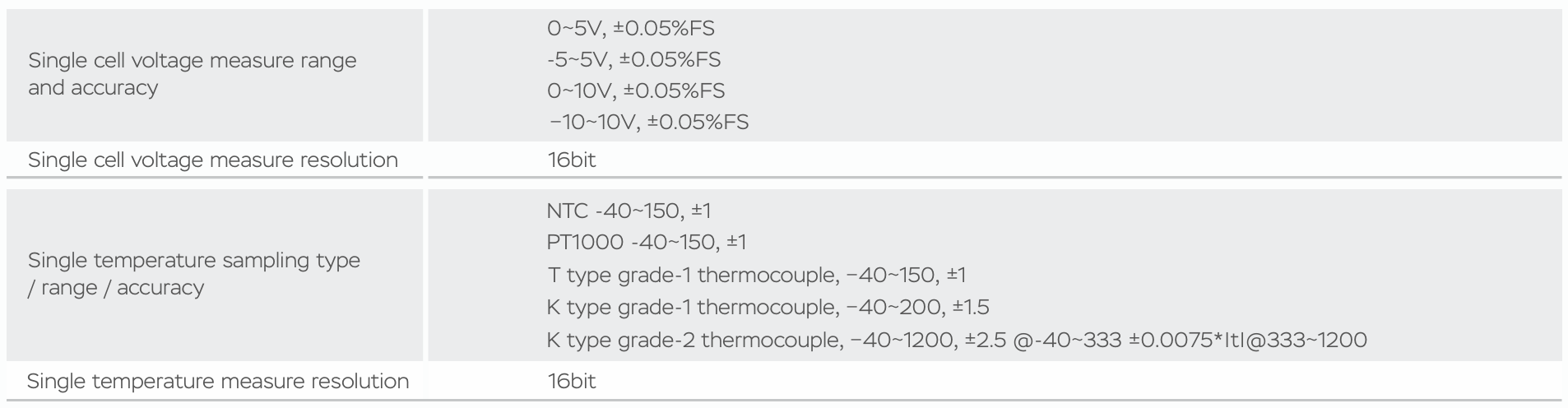

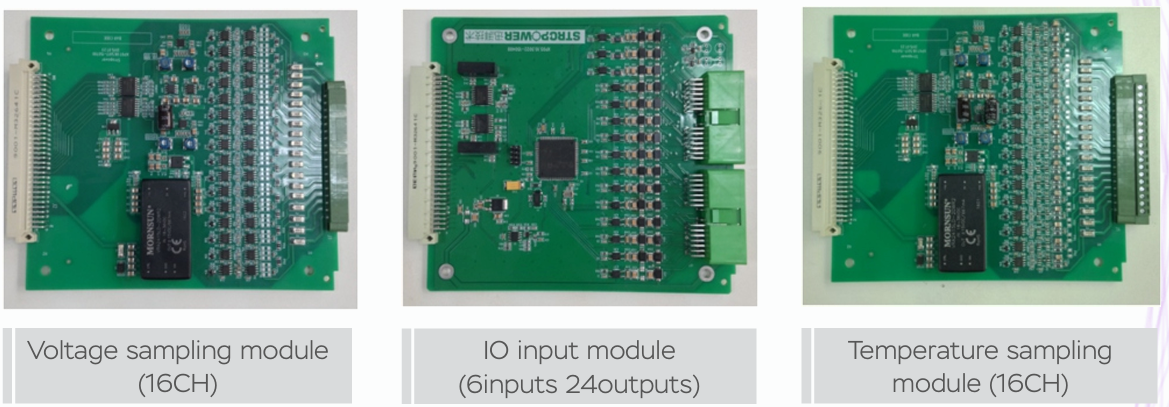

Auxiliary Sampling Performance And Configuration Parameters

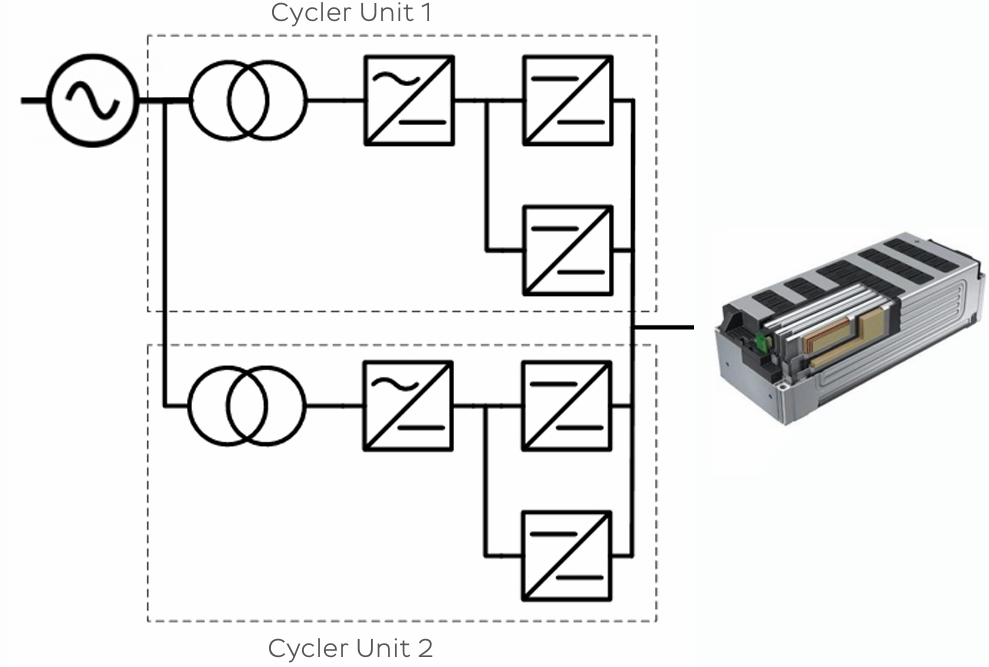

Flexible Modular Configuration

IVC module (cycler unit) is flexible for paralleling outputs between channels, Voltage sampling / Temperature sampling / Analog input module are flexible for configuration on purpose.

Stropower ASU (Auxiliary Sampling Unit) is one-stop solution for complete massive sampling demand.

Application Example: 48V System Test

Built-in real-time controller supports high-speed communication and 3ms data recording

High precision PID control algorithm, 3ms current response

The efficiency of the whole machine is high, not less than 85% under the rated load

No need to use power resistors to consume discharge energy

Does not pollute the power grid, does not affect other electrical equipment, power factor greater than 0.99, current harmonics less than 5%

Application User Case

undefined

Online message

* Note: Please be sure to fill in the information accurately and keep the communication open. We will get in touch with you as soon as possible