Solution

Powerful Testing System for EV batteries

Powerful Testing System for EV batteries

It is undoubtable that there are bunch of things need to be taken into consideration and test-verified before you qualify a certain type or model of power batteries for EV or xEV, and there will be a long list of test items together with test requirements and process control which normally not only technically but also commercially weighted for the project planning.

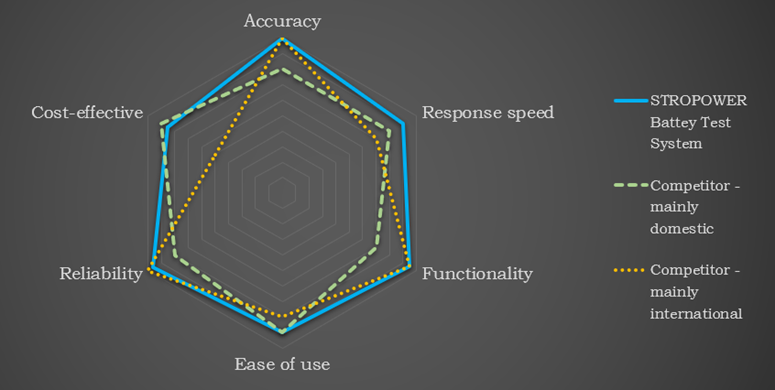

In case of the main frame of battery testing apparatus – battery cyclers (charging and discharging machine), the general requirements result in performance – power demand, functionality, accuracy and response speed, as well as in user concerns – reliability (for long runs), cost-effective and ease of use.

Came from several comparison test and long-time projects’ comments of real customers, Stropower battery testing system (cyclers – cell/module/pack) remained a trustable yet favorite choice when make a comprehensive evaluation. For example, the basic accuracy to measurement and control error: not only the voltage and current has already over passed 0.02% F.S. but also for research purpose – 10ppm F.S. are available, and it is first time ever Stropower proposed a time accuracy measurement method for the industry.

Fig.1 Comprehensive evaluation of battery cyclers (survey from 20 comments)

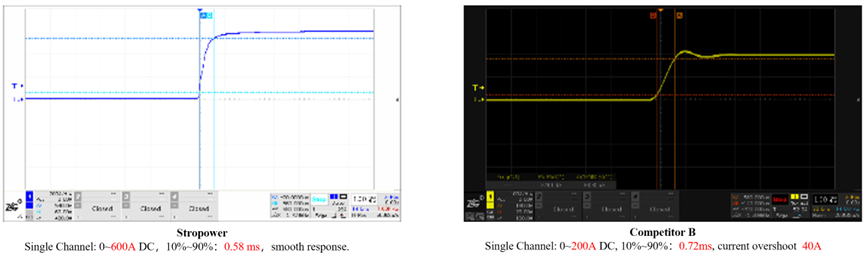

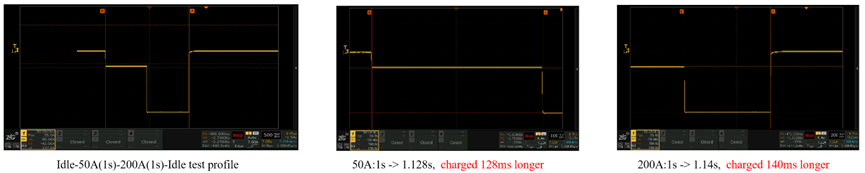

In the past there is no similar consideration because of the difficulty to control the response speed in a very narrow tolerance plus a flat and smooth transient characteristic, without this the time accuracy to defined user test program is no-easy task, and because of the latent delay and miss-controlled transient the deviation to the

original test prediction grows – this is more evident when battery suffers pulse tests for simulating to road drive patterns which normally result in a slight aggravated aging of battery service life.

Fig.2 Response characteristic with single channel

Fig.3 The time delay during charging and switching

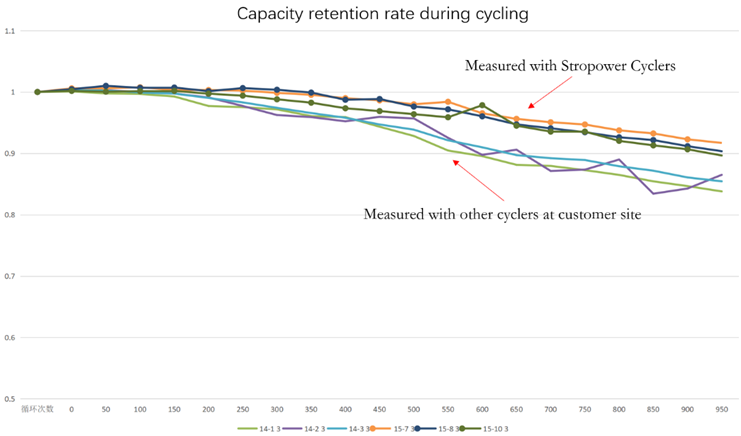

Fig.4 Capacity retention rate during cycling with different cyclers

The parameters for testing accuracy and response speed are highly related to hardware design of the charging-discharging machine (though there are software control techniques behind the fact), but for general user case what’s more concerned is how to easily convert test specifications to test programs in the server software, especially when planning a long term cycling test with events like RPT (reference parameter test), charging with SoC-temperature defined matrix for fast-charging dynamic strategy, pulse sequencies with self-adaptive patterns, and climate change linkage during the process.

The unique double-rail control stream for Stropower charging-discharging machines powered by its ENOVA server software provides all-situation considered and easy-to-use programming interface for users to quickly yet precisely finish the set up. Comparing to single chain process generally adopted on the market which can’t offer parallel threads running simultaneously, the double-rail control stream can empower customer with several same time process following the main power test to batteries. It is therefore a precise SoC, temperature or swelling force sensor process monitoring, variable sampling steps, co-pilot math works … etc. are now up to wish.

PRODUCT - Xi'an Stropower Technologies Co., Ltd