Solution

Application of Ultra-high Precision Battery Test

Application of Ultra-high Precision Battery Test

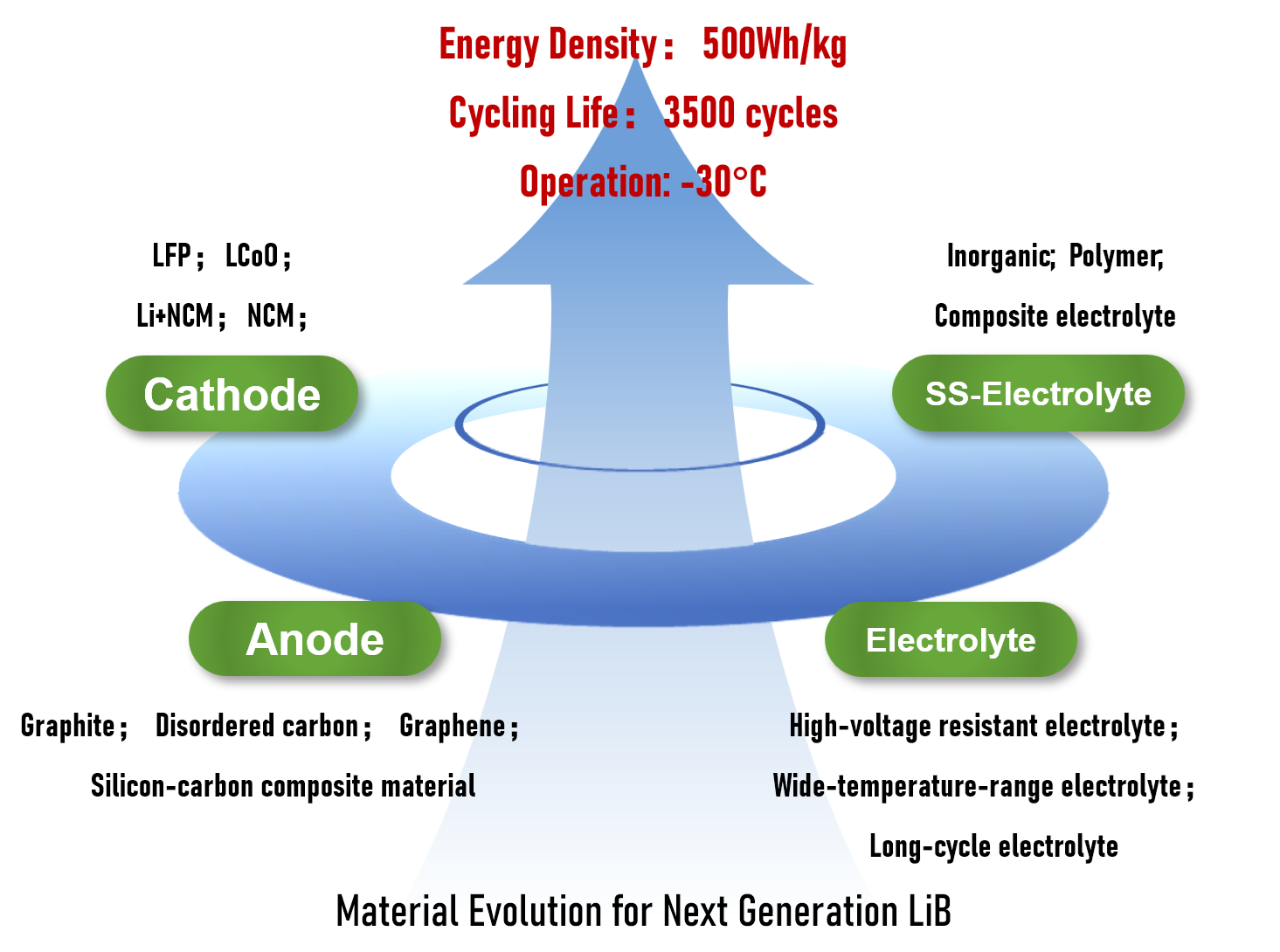

Background for the UHPC Application - the Material Evolution for Lithium-ion Batteries

The evolution path of lithium - ion batteries for higher energy density and longer service life from the perspective of electrode materials and electrolyte materials mainly lie in:

• Anode Materials

• High - Nickel Cathodes: Increasing the nickel content in layered oxide anodes such as NMC and NCA can significantly improve energy density1. Nickel can store more lithium ions than cobalt1. Materials with a higher nickel content, like NCM 811, are being developed and optimized to achieve higher energy densities.

• Silicon - Based Anodes: Silicon has a much - higher theoretical capacity than graphite. However, it suffers from volume expansion and mechanical degradation during charge - discharge cycles1. To address this, silicon - carbon composites, nanostructured silicon, or silicon oxides are being used to mitigate the expansion problem and improve cycle life.

• Lithium Metal Anodes: Lithium metal anodes have a high theoretical capacity. But the dendrites formed during cycling pose safety risks and shorten the cycle life1. Solid electrolytes and advanced surface coatings are being explored as potential solutions to improve their safety and stability.

• Cathode Materials: Graphite is a commonly used cathode material. To improve energy density, research is focused on developing new materials and optimizing existing ones. For example, the use of nanoscale composite materials and two - dimensional materials can increase the specific surface area of electrode materials, promote the rapid insertion and extraction of lithium ions, and reduce capacity loss. In addition, surface modification techniques such as coating or encapsulation can improve the surface properties of electrode materials, enhance their corrosion resistance and stability, thereby prolonging the service life of batteries.

• Solid Electrolytes: Solid electrolytes such as ceramic - or sulfide - based electrolytes are being developed to replace liquid electrolytes. They have high ionic conductivity, better safety (non - flammable), and the potential to be used with lithium - metal anodes, which can improve energy density. At the same time, by improving the synthesis method, interface modification, and microstructure control of solid electrolytes, the cycle stability and energy density of batteries can be effectively improved.

• Ionic Liquids and Polymer Electrolytes: Ionic liquids are non - flammable and high - temperature - resistant electrolytes that can improve battery safety and stability, and may also increase energy density. Polymer electrolytes are flexible and can be customized according to the needs of solid - state applications, which helps improve safety and may increase volumetric energy density.

• Optimization of Traditional Liquid Electrolytes: For traditional liquid electrolytes, efforts are being made to optimize the selection and ratio of organic solvents, develop new electrolyte salt systems, and introduce functional additives. These measures can improve the conductivity, stability, and interface properties of electrolytes, thereby enhancing battery performance and prolonging service life.

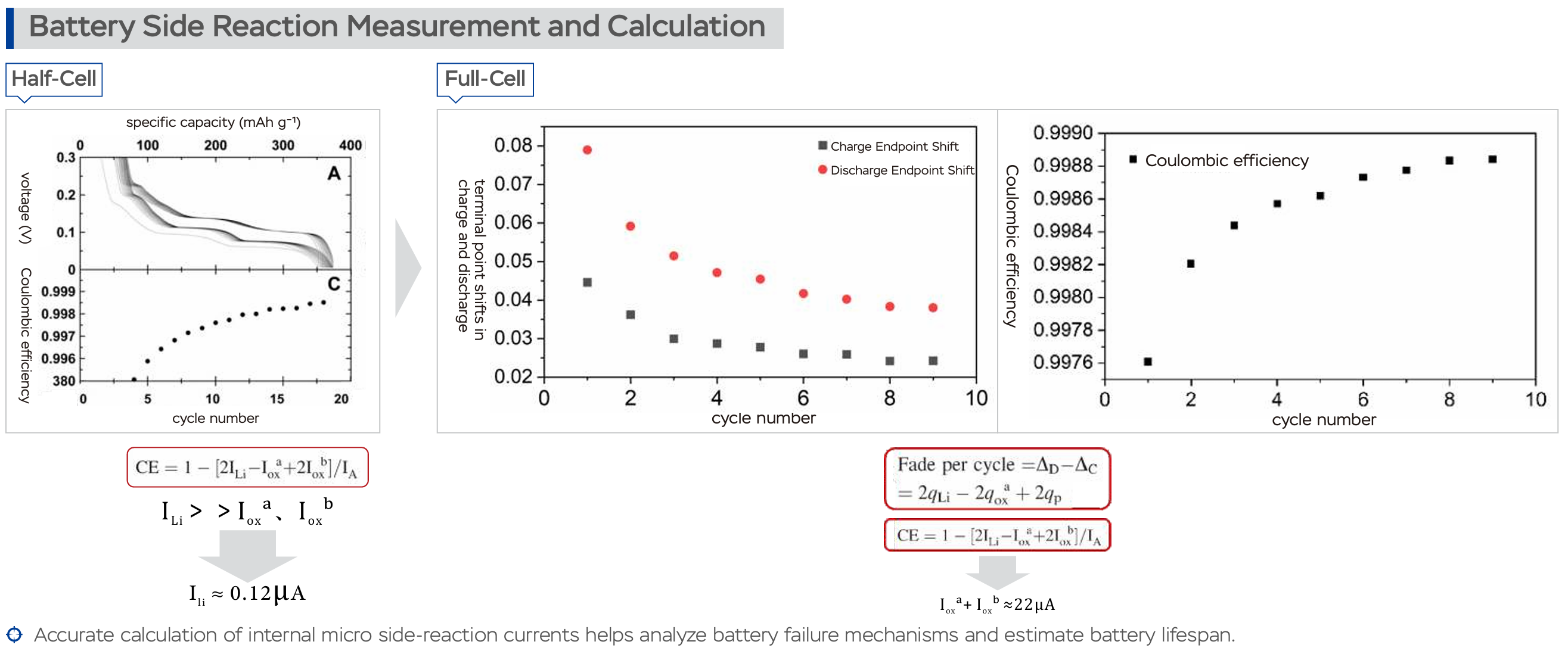

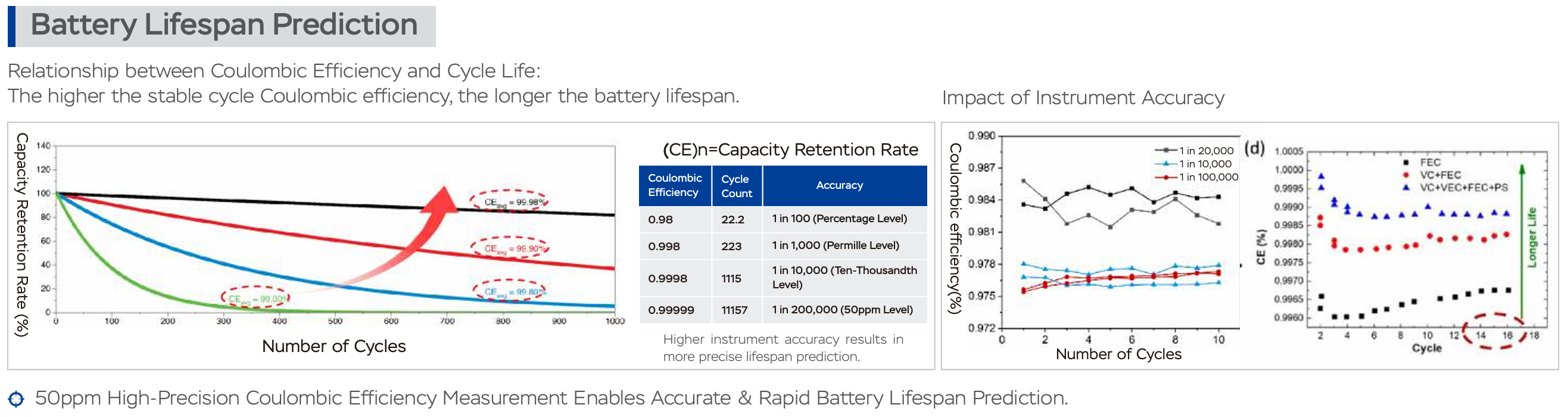

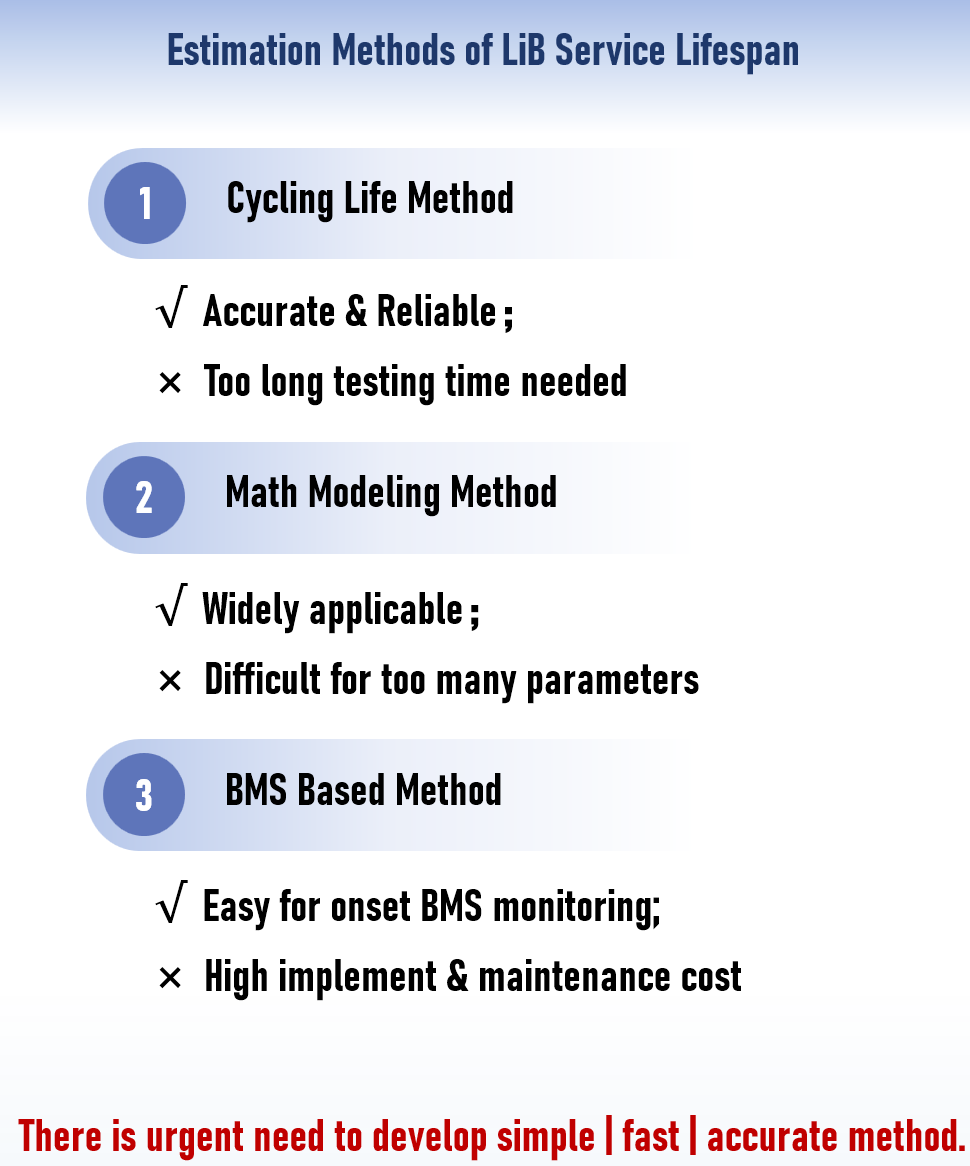

The solution around Questions - 1 : Rapid life prediction of lithium-ion batteries reduces the unpredictability of profits and losses

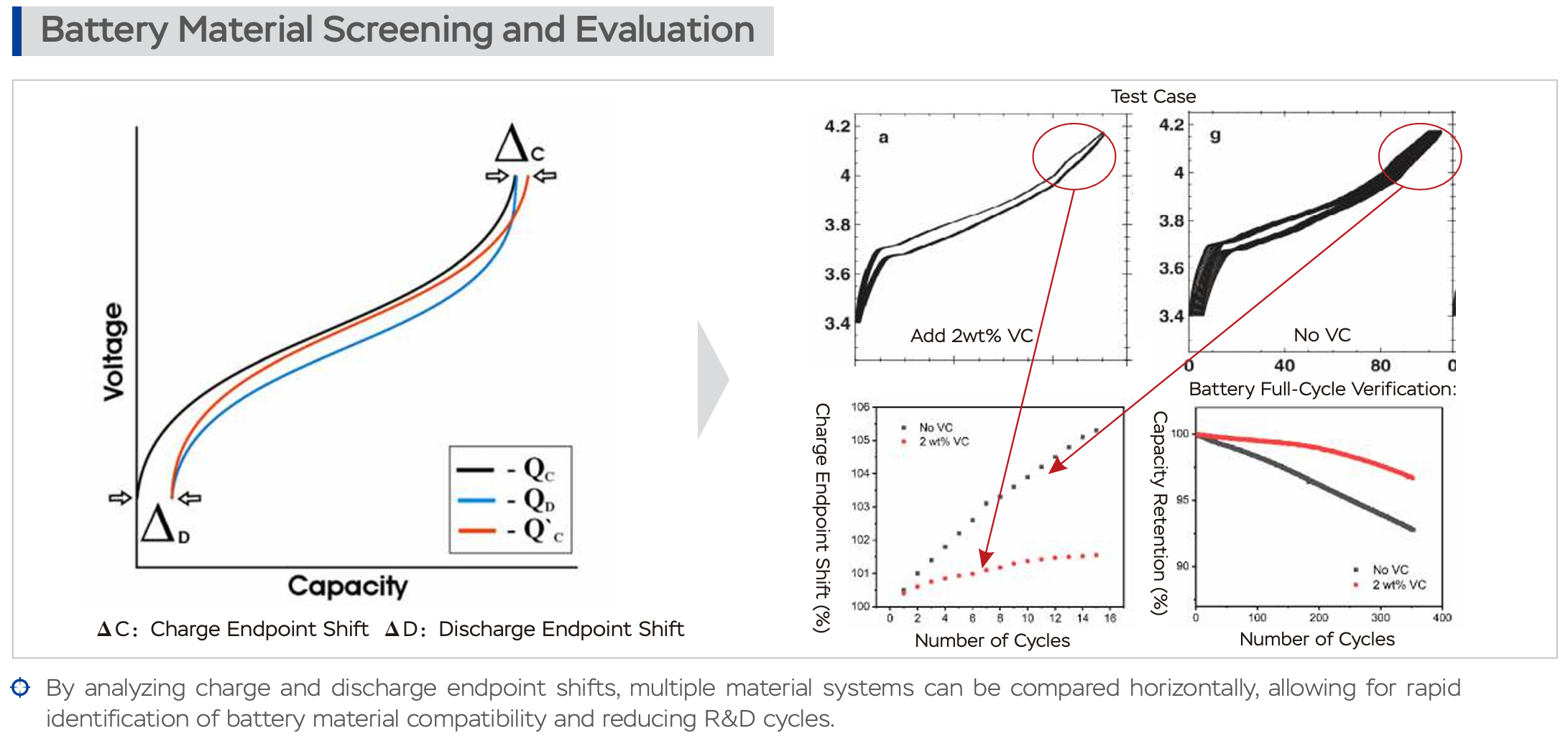

The solution around Questions - 2 : By rapidly analyzing battery performance, the R&D cycle can be shortened, product competitiveness can be enhanced, and cost reduction and efficiency improvement can be achieved

UHPC - Ultra-High Precision Battery Cycling Test can detect very micro scale electro-chemical material reactions and thus the failure mode of a long run of cycling