Testing Background and Purpose

Solution

Ripple Heating Test Solution for LiB

Ripple Heating Test Solution for LiB

Lithium - ion batteries experience a significant capacity drop at low temperatures due to several reasons related to electrochemical reactions and physical properties. Here are the main factors and corresponding countermeasures for heating batteries in EV or PHEV applications:

Reasons for Capacity Drop at Low Temperatures

- Slowed electrochemical reaction kinetics:

- At low temperatures, the rate of chemical reactions in the battery slows down. The movement of lithium ions between the positive and negative electrodes is inhibited, leading to a decrease in the ability of the battery to release and store energy, thereby reducing the available capacity.

- Increased internal resistance:

- The electrolyte's viscosity increases at low temperatures, which restricts the movement of ions. Additionally, the resistance at the electrode - electrolyte interface may increase. These factors result in increased internal resistance of the battery, causing more energy to be dissipated as heat during charging and discharging, and reducing the battery's efficiency and available capacity.

- Formation of lithium plating:

- At low temperatures, the lithium - ion deposition rate on the negative electrode surface may be faster than its diffusion rate into the electrode material. This can lead to the formation of lithium plating on the electrode surface, which not only reduces the active material available for electrochemical reactions but also poses a safety risk.

Countermeasures for Heating Batteries in EV or PHEV Applications

- PTC heaters:

- Positive temperature coefficient (PTC) heaters are often used. These heaters have a resistance that increases with temperature. They are installed in the battery pack and can heat the battery when the temperature is low. PTC heaters are simple in structure, reliable in operation, and can quickly raise the battery temperature to a suitable range.

- Heating films:

- Heating films are another common heating method. They are usually made of materials with good thermal conductivity and can be attached to the surface of the battery pack. By applying an electric current, the heating film generates heat, which is transferred to the battery to increase its temperature. Heating films can provide uniform heating and are easy to install and control.

- Liquid heating systems:

- Many EVs and PHEVs use liquid heating systems. These systems circulate a heated liquid, such as a glycol - water mixture, through channels in the battery pack. The liquid absorbs heat from a heat source, such as the vehicle's engine coolant or an electric heater, and transfers it to the battery. Liquid heating systems can effectively control the battery temperature and ensure uniform heating across the battery pack.

- Intelligent thermal management systems:

- These systems use temperature sensors to monitor the battery temperature in real - time and adjust the heating power according to the actual temperature. They can also coordinate with other components in the vehicle, such as the air - conditioning system, to optimize the overall thermal management. Intelligent thermal management systems help to improve the efficiency of battery heating and reduce energy consumption.

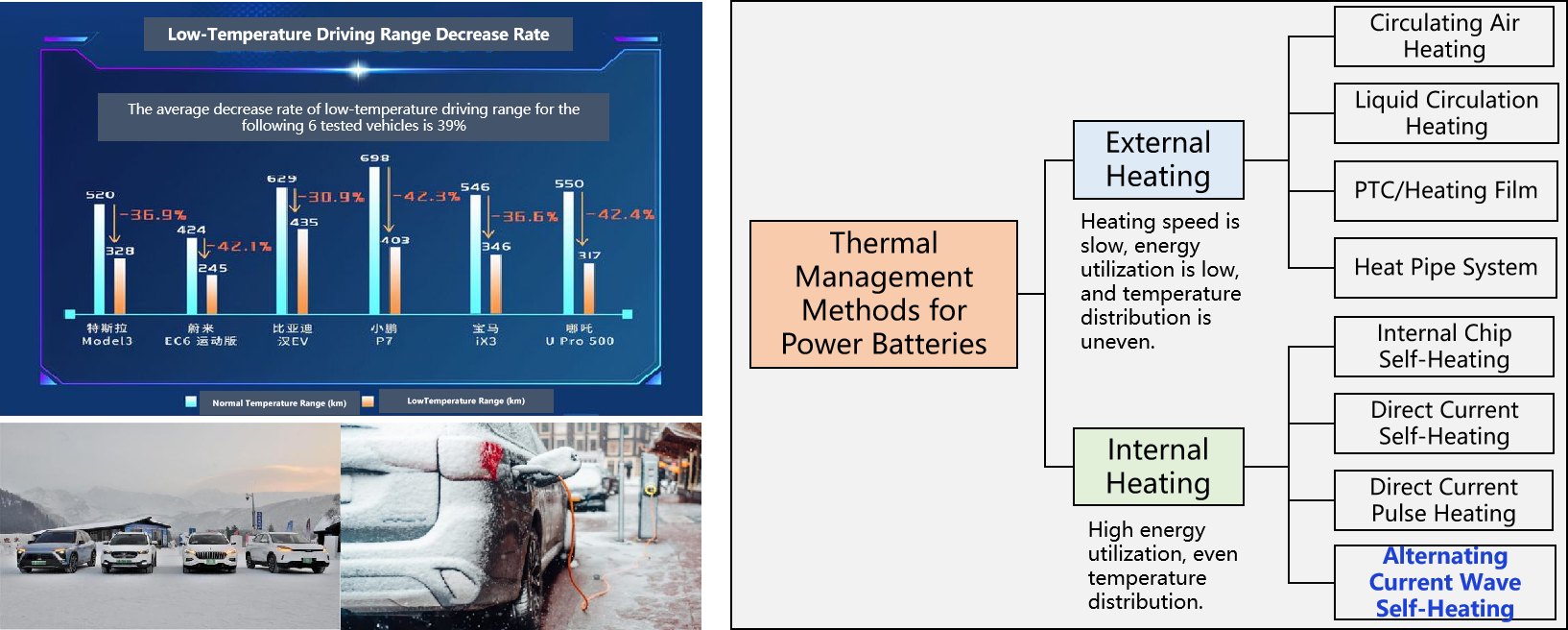

◆ In low-temperature environments, the internal resistance of lithium-ion power batteries increases sharply, leading to issues such as reduced range in new energy vehicles, insufficient cold start power, charging difficulties, and low charging efficiency.

◆ Effective heating of lithium-ion batteries is required at low temperatures to ensure their normal operation. Among the heating methods used in thermal management for power batteries, AC ripple self-heating rapidly raises the battery temperature through periodic charging and discharging. This method also offers advantages such as high energy efficiency and uniform temperature distribution.

AC Ripple Self-Heating Heat Generation Mechanism

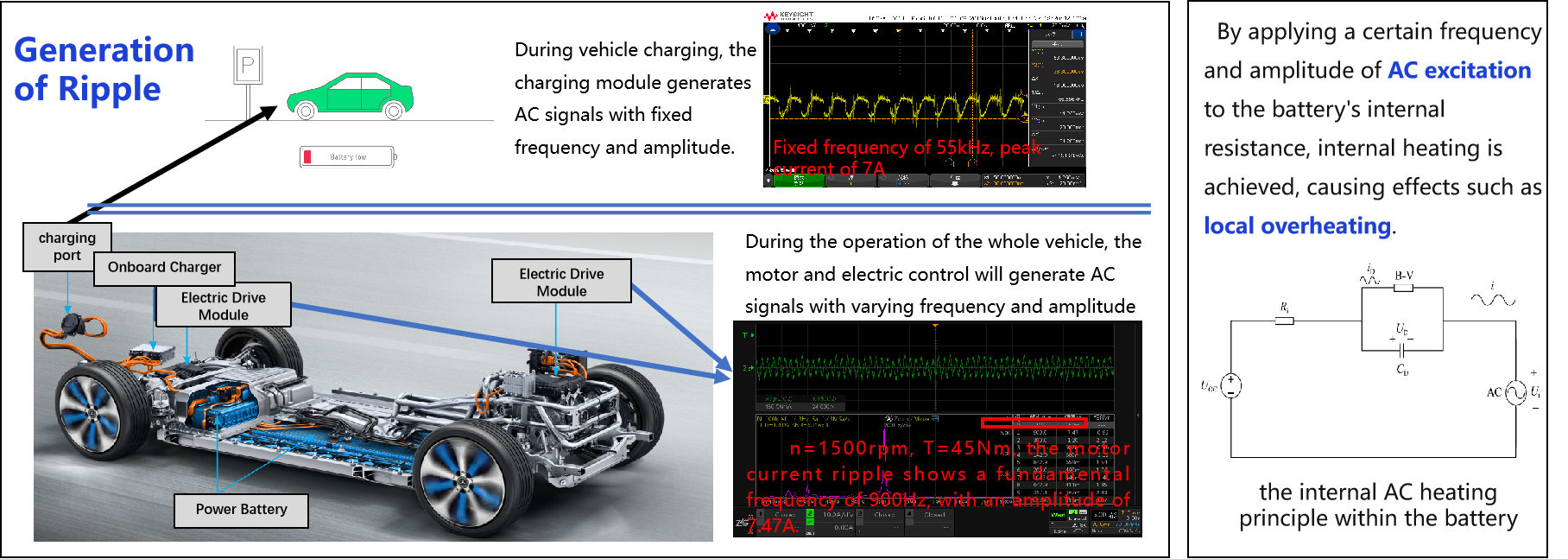

◆ Generation of AC Ripple: When the electric vehicle is in states such as energy recovery, vehicle operation, or battery charging, AC ripples are generated on the high-voltage bus line.

◆ AC Ripple Self-Heating: In the BEV system, the motor's inductance is used as a load. By modifying the motor control strategy to produce AC ripples with specific amplitude and frequency, the power battery can self-heat.

Ripple Heating Test Solutions

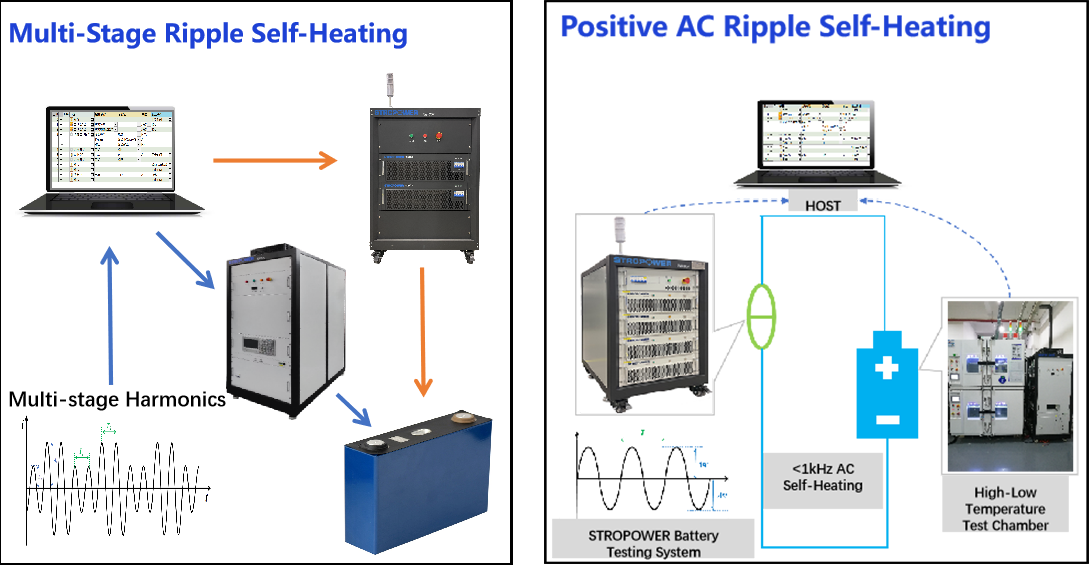

◆ 1)Chip-Level Ripple Self-Heating

◆ 2)Pack-Level Ripple Self-Heating