-

Products

-

-

General Compliance Tests

General Compliance Test for National Standards & Auto Companies

General Compliance Test for National Standards & Auto Companies

-

MP Cycling Life Test

Cycling Life Test for Mass Production Batteries.

Cycling Life Test for Mass Production Batteries.

-

MES Integrated Environment Testing

MES tests for environmental & linkage events adapted test

MES tests for environmental & linkage events adapted test

-

High Rate DAQ for Battery Over-discharging Test

High Rate DAQ for Battery Over-discharging Test

High Rate DAQ for Battery Over-discharging Test

Solution

-

-

-

-

About Stropower

-

——

Solution

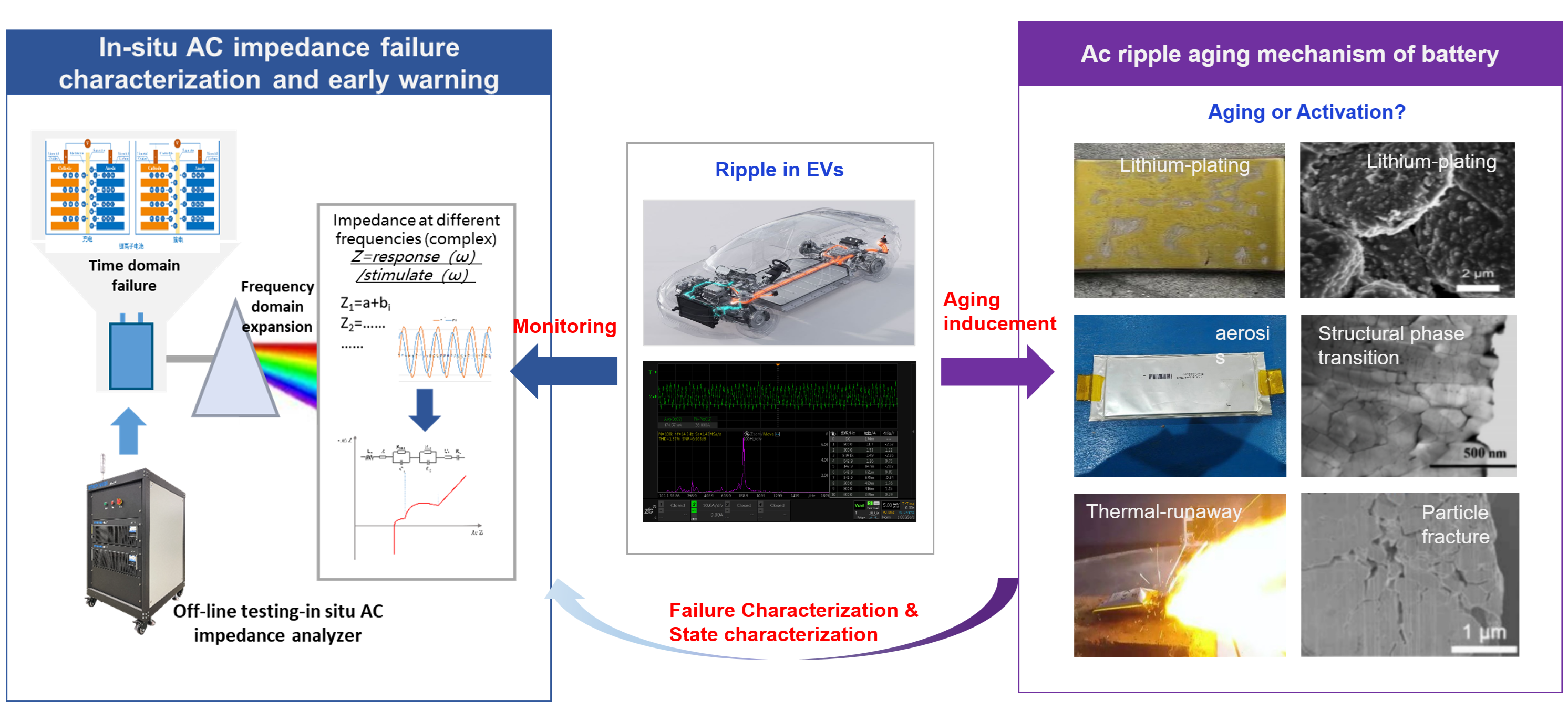

Battery Aging Analysis and Pre-failure Warning Test

Battery Aging Mechanism Analysis and Pre-failure Warning Application of Ripple Technologies

Background for the demand of battery aging mechanism analysis and pre-warning

2020~2023: Continuous growth of battery production & sales volume (traction power batteries for xEVs | energy storage) But: Overall growth rate is decreasing year by year (falling off a cliff in 2023).

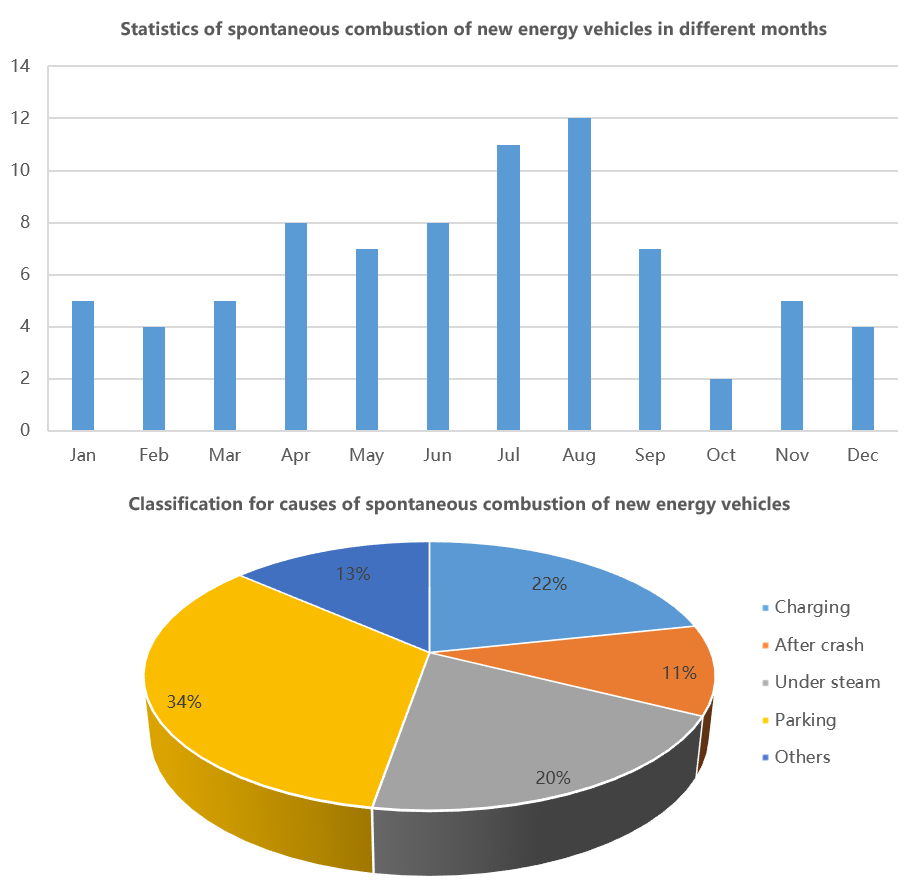

With rapid rising of EVs, the spontaneous combustion accidents caused by lithium-ion battery failure has also increased sharply; More than 4,000 spontaneous combustion accidents of xEV in 2023 (about 0.3‰ of held qty.), 50% are related to batteries.

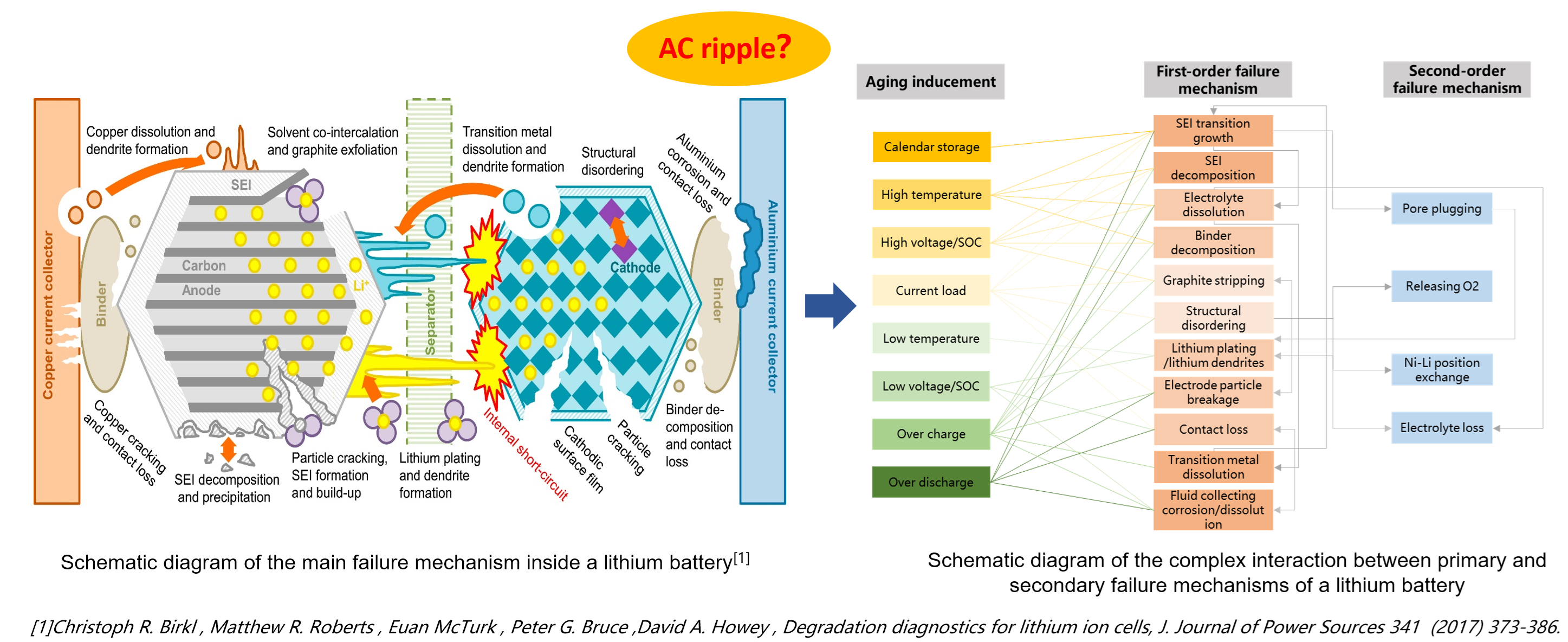

Electro-chemical Mechanism for Lithium-ion Battery's Aging and Degradation - The Contribution of AC Ripples

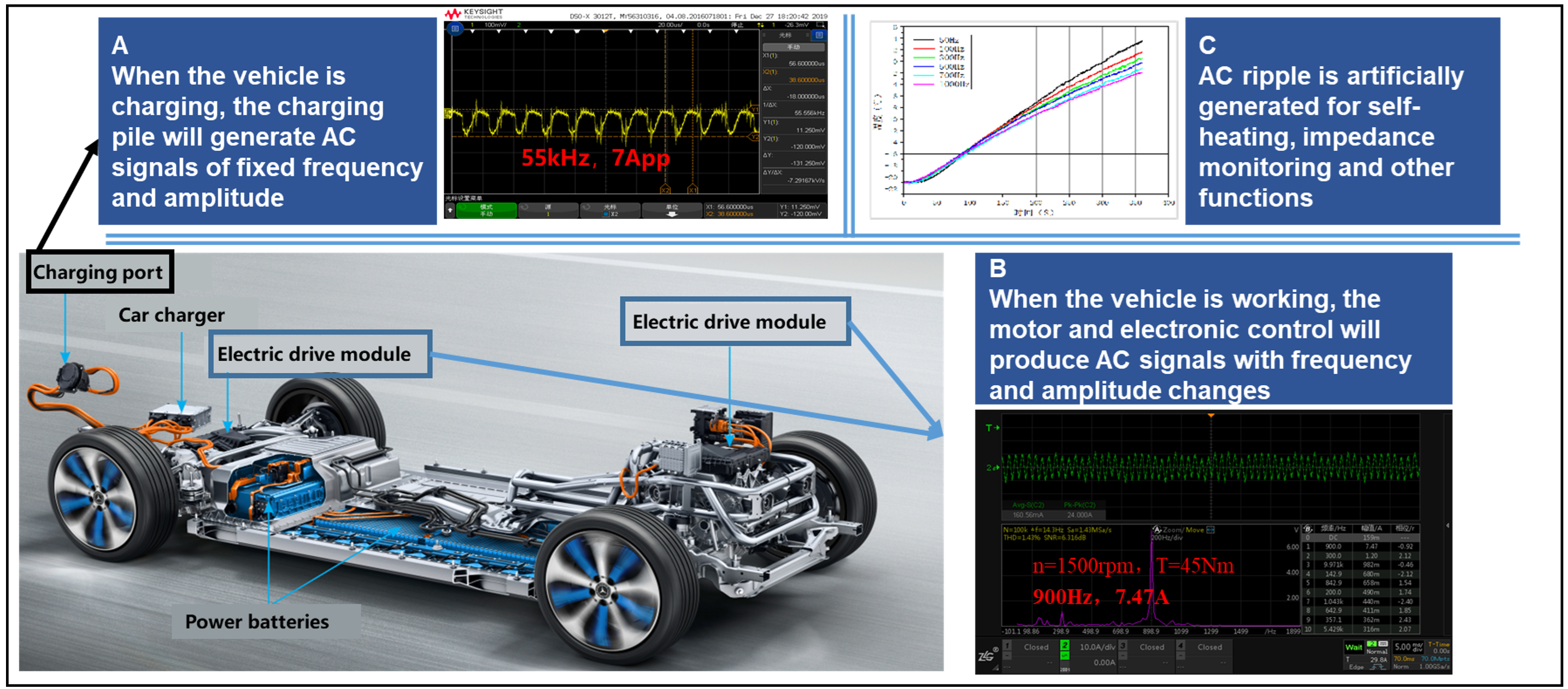

Lithium battery failure inducements: High/Low temperature environment, voltage, over-charge ,over-discharge etc. A new question rarely talked about: What is aging impact of AC ripple?

The drivetrain battery is not exposed to direct current only, the AC component (ripple) can reach up to 20%~30% of the DC power.

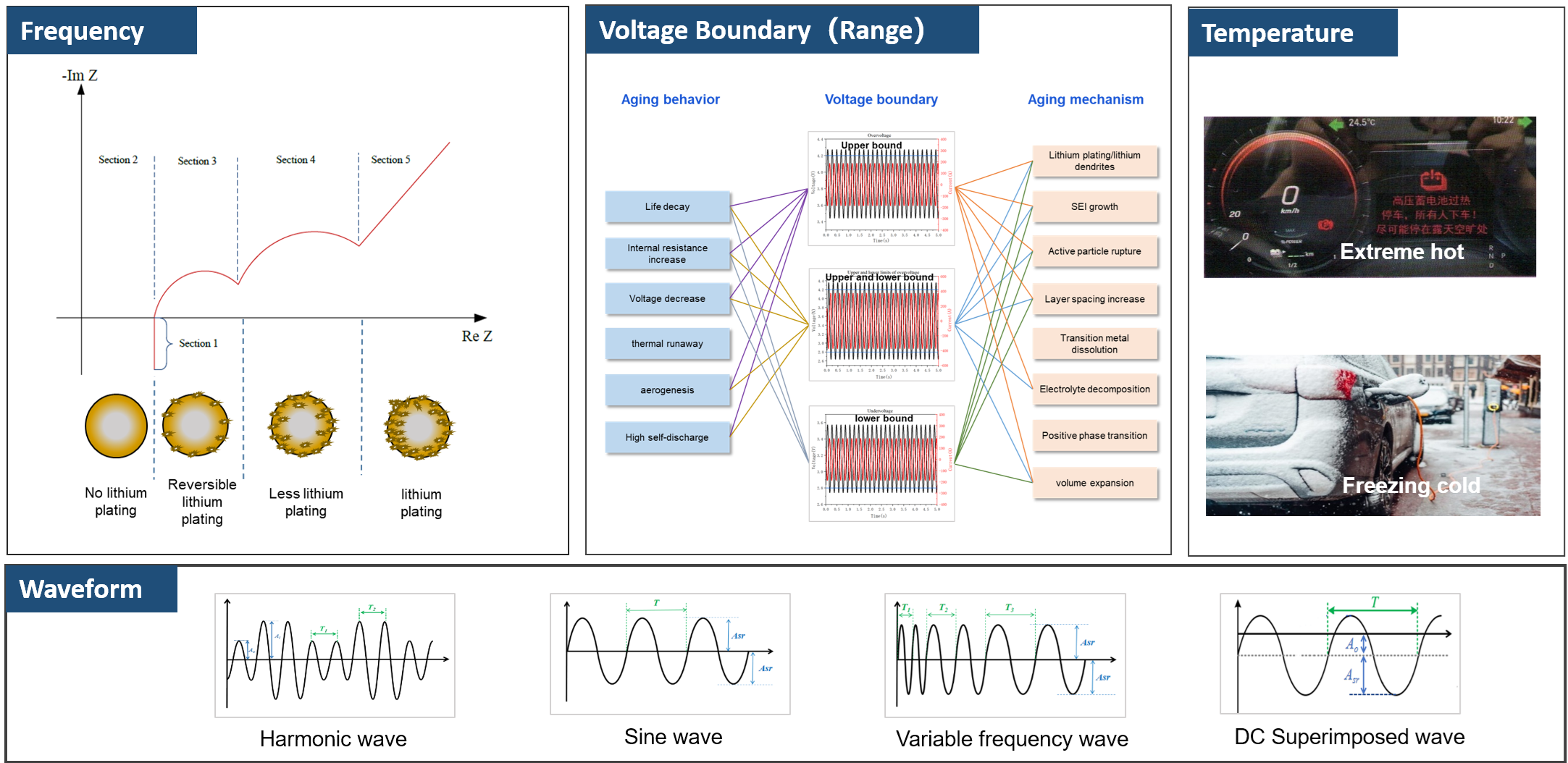

Some secondary causes of AC ripple effects on battery aging mechanism . . .

Test & Measurement with Stropower Solution to Detect the Mechanism and Model

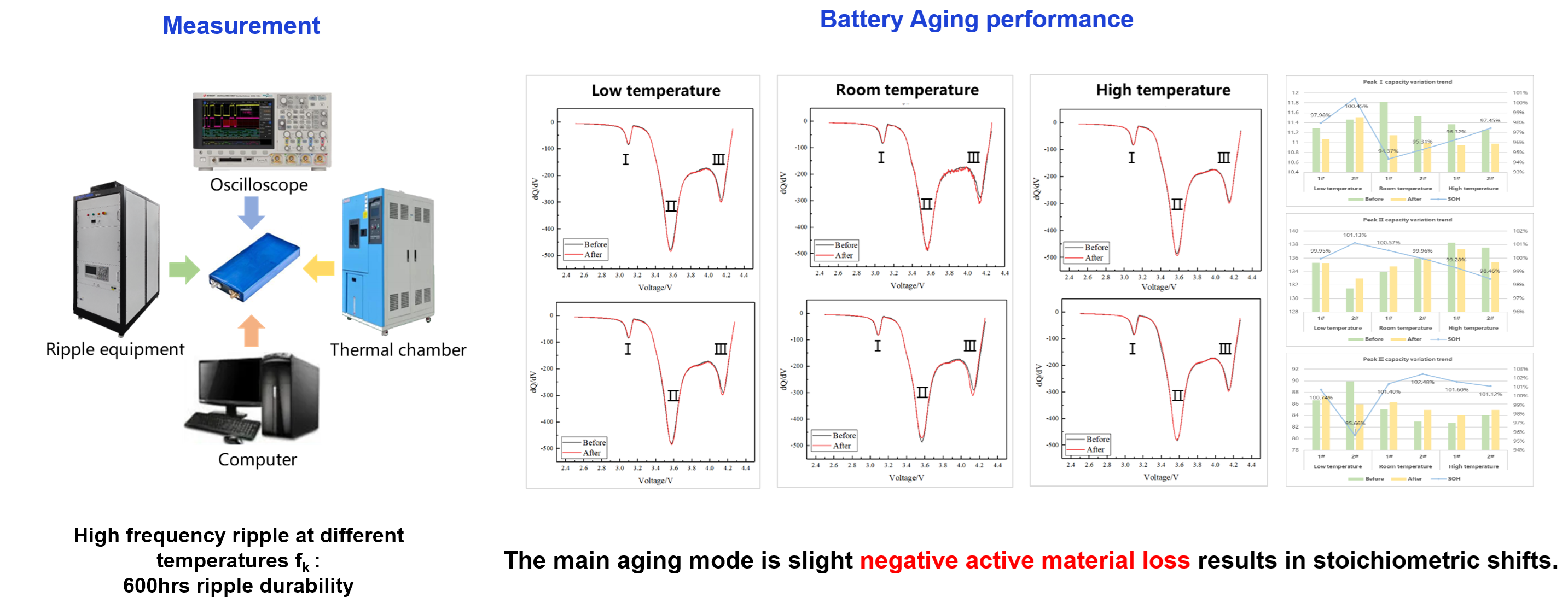

Aging mechanism analysis of characteristic high-frequency ripple on batteries,Specific high-frequency ripple fk long-cycle injection has relatively little effect on battery capacity.

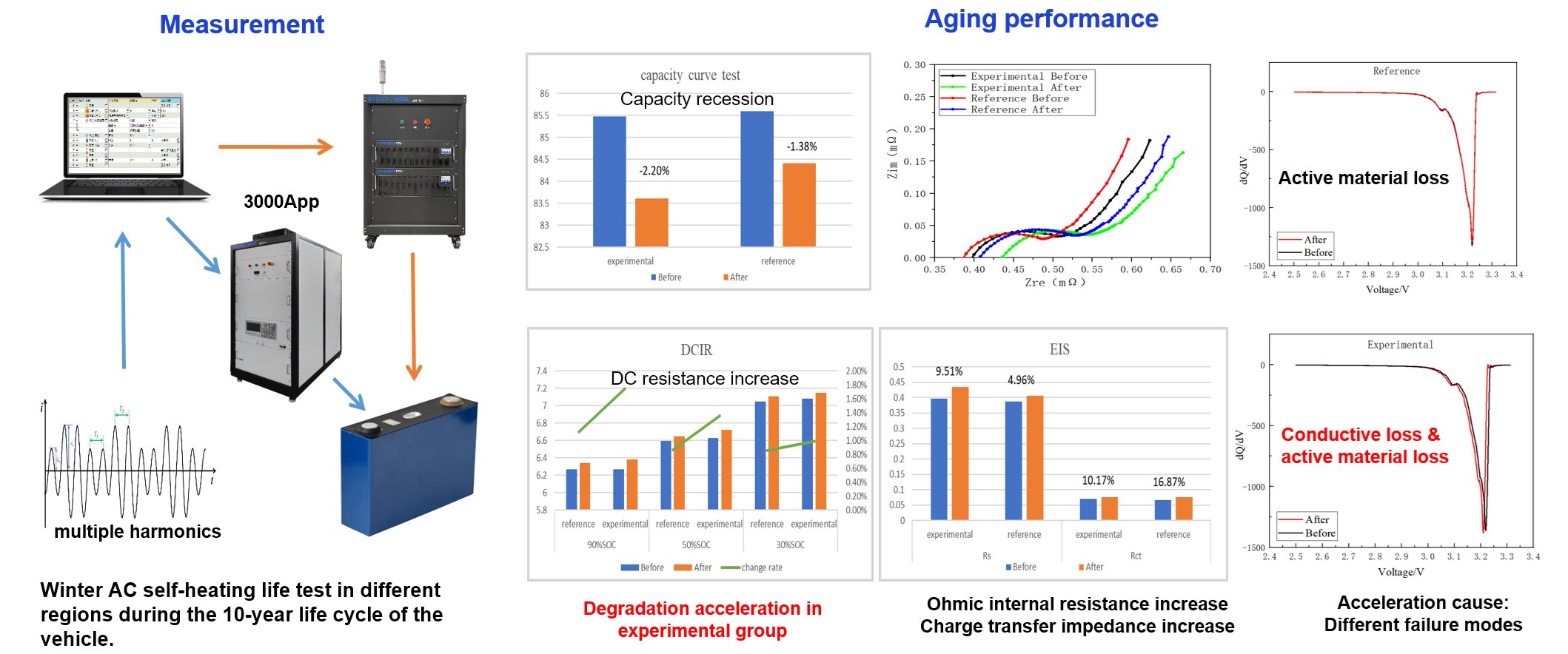

AC harmonics self-heating durability – Aging mechanism analysis: Conductive loss & active material loss as the leading internal resistance degradation

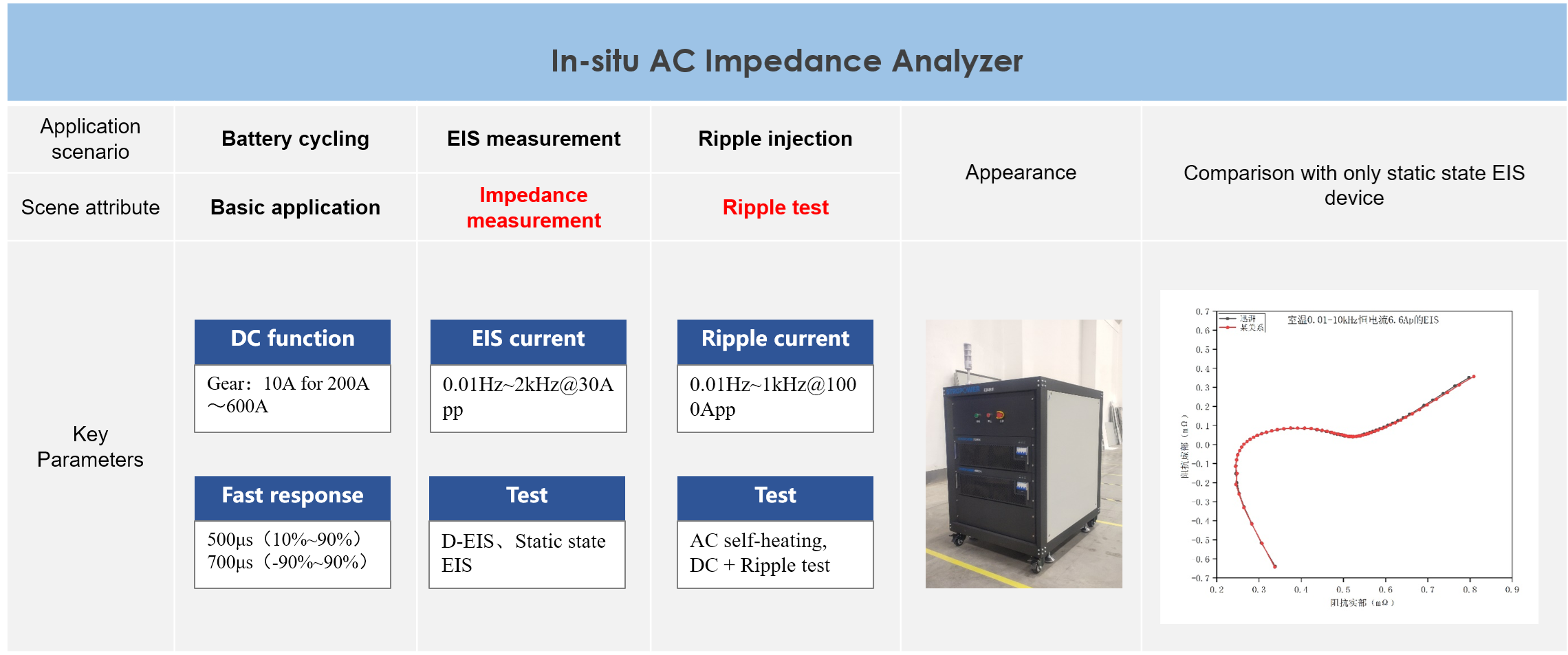

Based on the basic DC charge/discharge test, we introduced the In-situ AC impedance analyzer, which covers the DC and AC test demand, and can meet the dual research needs of in-situ AC impedance and battery ripple-based service life.

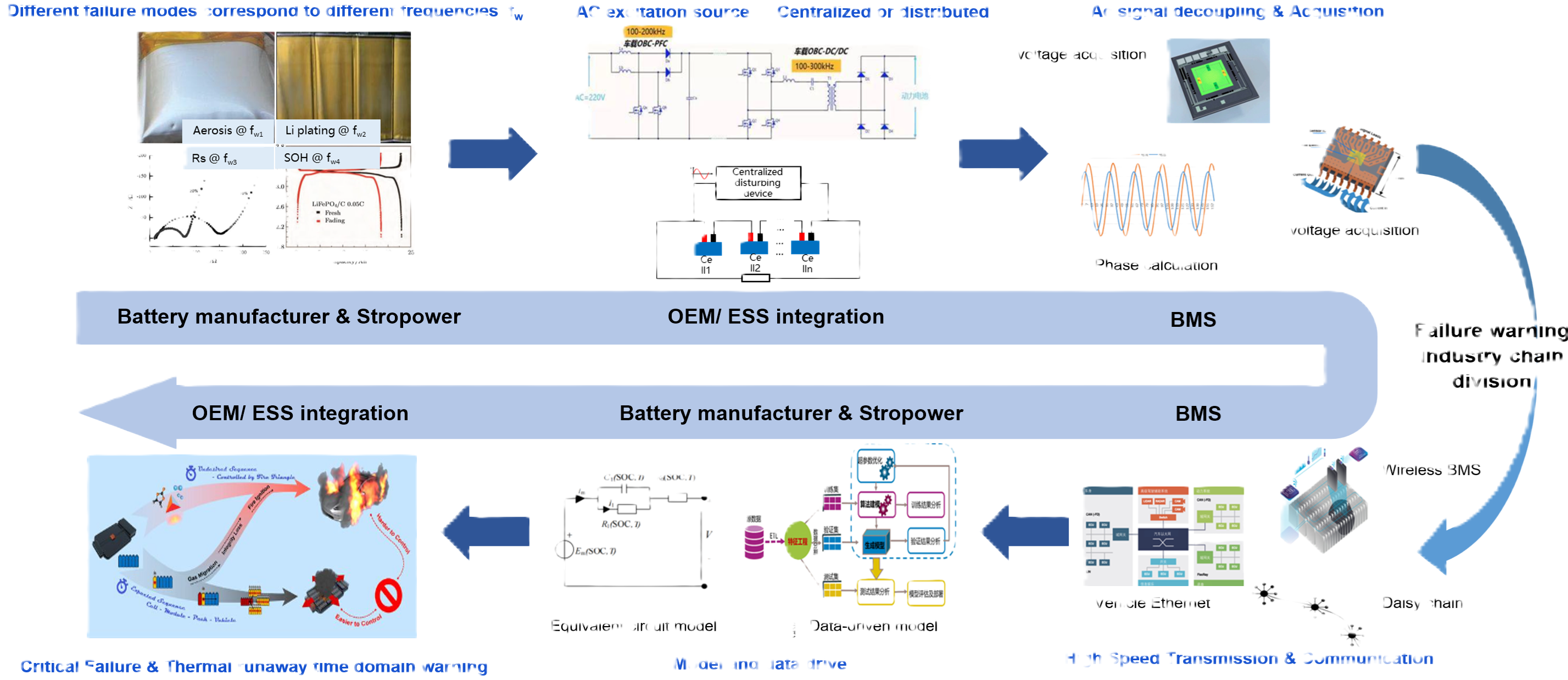

Through EV’s characteristic AC fw coupling – excitation – acquisition – communication – modeling, to achieve critical failure and thermal runaway monitoring and time-domain early warning.

2nd Floor, Building 3, East Zone, Modern Enterprise Center, No.2 Zhangba Wu Road, Yanta District, Xi 'an, Shaanxi

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home