-

Products

-

-

General Compliance Tests

General Compliance Test for National Standards & Auto Companies

General Compliance Test for National Standards & Auto Companies

-

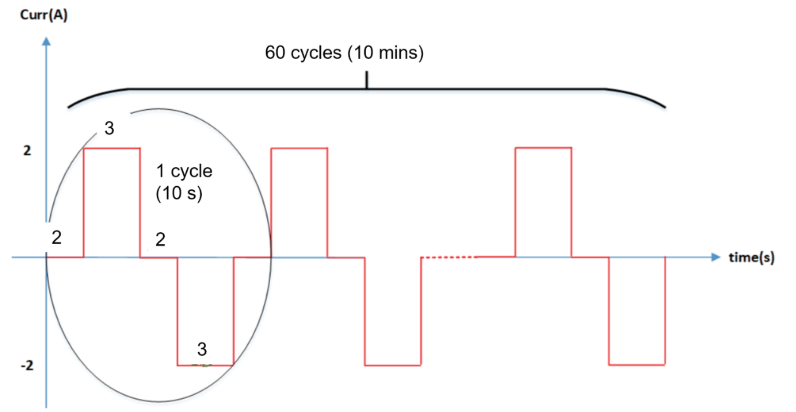

MP Cycling Life Test

Cycling Life Test for Mass Production Batteries.

Cycling Life Test for Mass Production Batteries.

-

MES Integrated Environment Testing

MES tests for environmental & linkage events adapted test

MES tests for environmental & linkage events adapted test

-

High Rate DAQ for Battery Over-discharging Test

High Rate DAQ for Battery Over-discharging Test

High Rate DAQ for Battery Over-discharging Test

Solution

-

-

-

-

About Stropower

-

SOLUTION

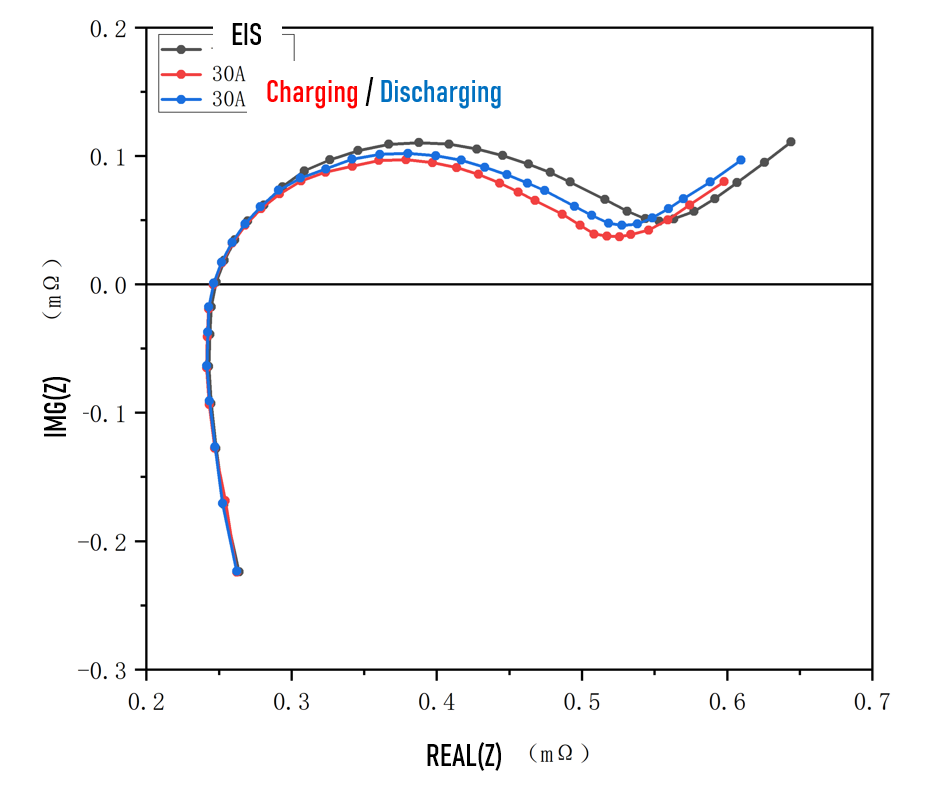

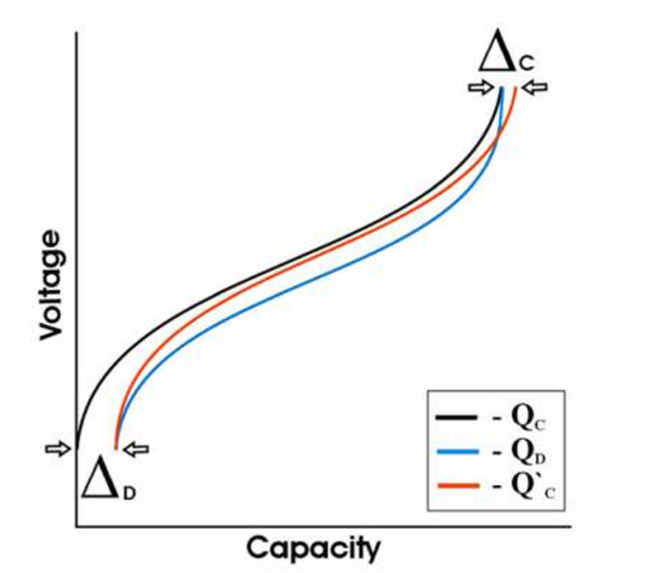

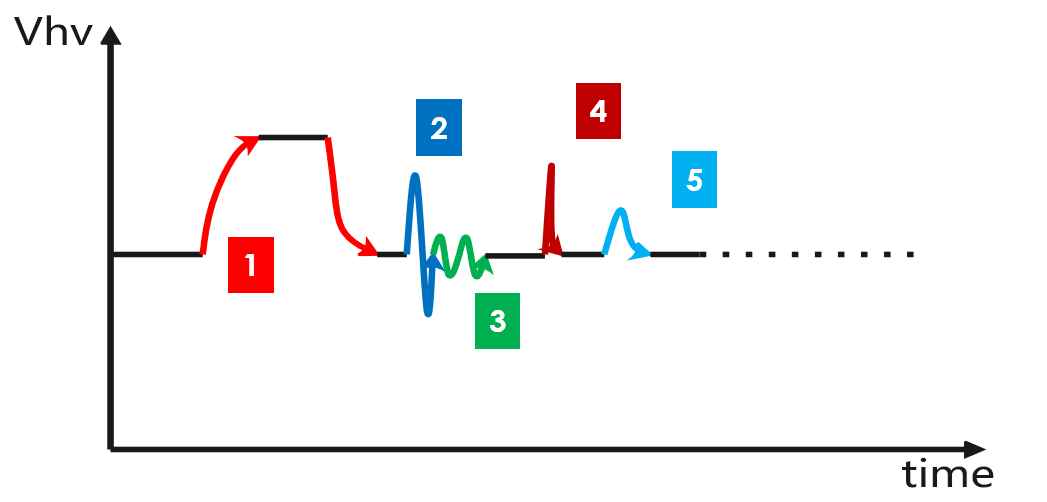

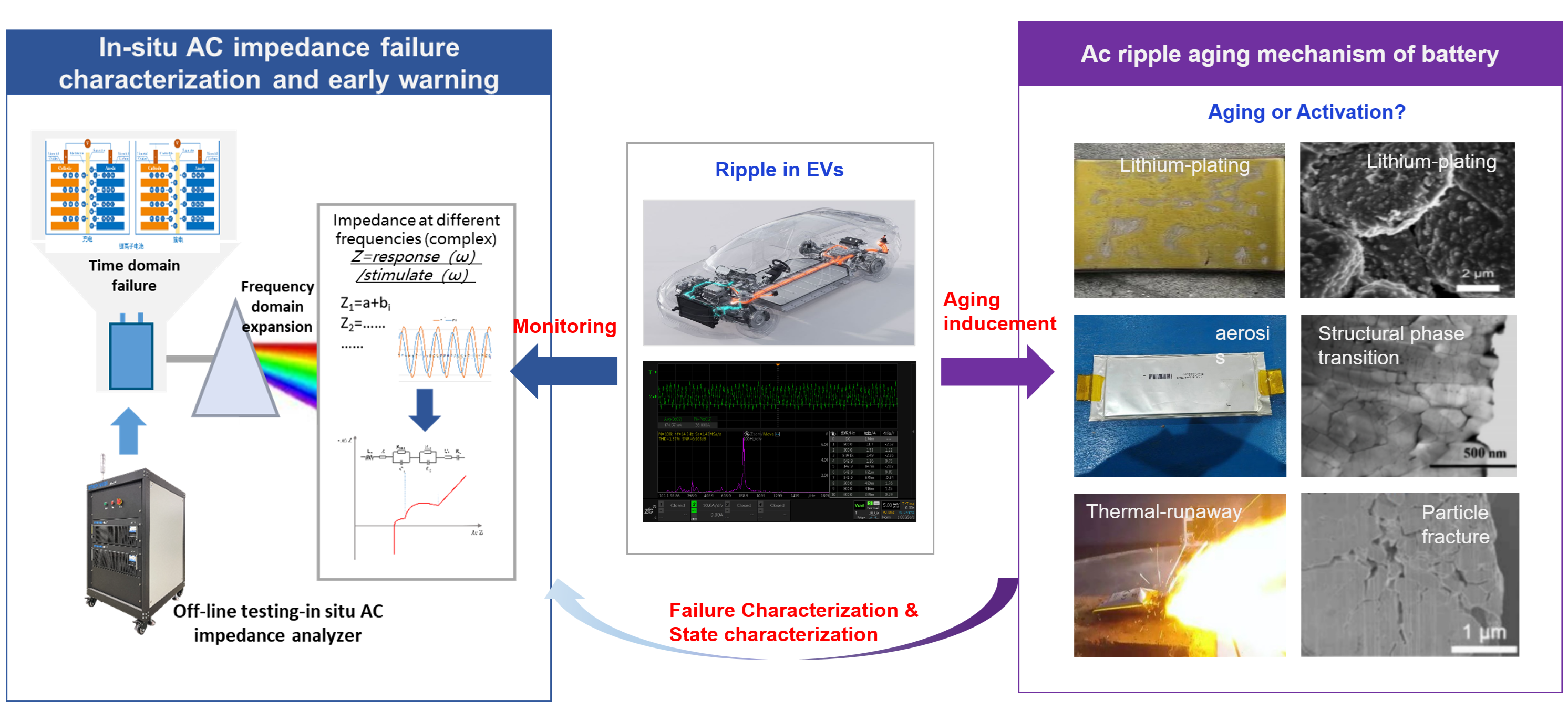

Dynamics & Transients of EV High Voltage Power Network

Battery Aging Analysis and Pre-failure Warning Test

Time Accuracy & Control Speed - Making Differences between Test Abilities

PRODUCT CENTER

Pre-charging Load and Fault Emulator

HV Pulse Generator for HVEE Test

NEWS

ABOUT US

Xi'an Stropower Technologies Co., Ltd

Stropower dedicates to providing power battery testing and power battery emulation solutions to global customers. Our products have been wildly applied in testing the key components of electric vehicles.Areas include power battery,electric motor,motor controller,vehicle controller,BMS,charging system,and supercapacitor.

2nd Floor, Building 3, East Zone, Modern Enterprise Center, No.2 Zhangba Wu Road, Yanta District, Xi 'an, Shaanxi

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home